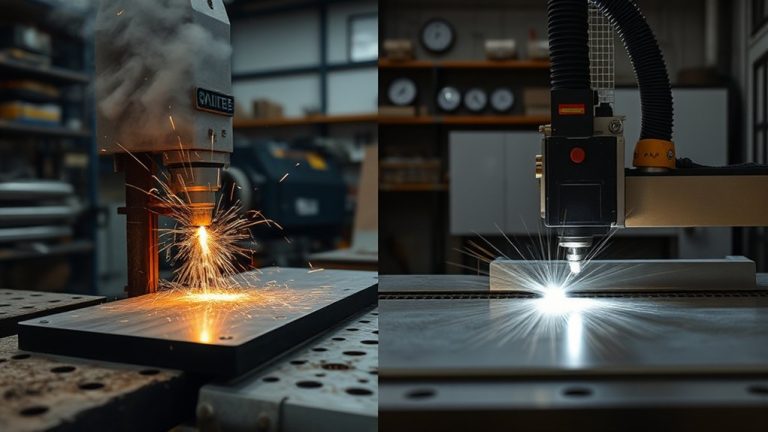

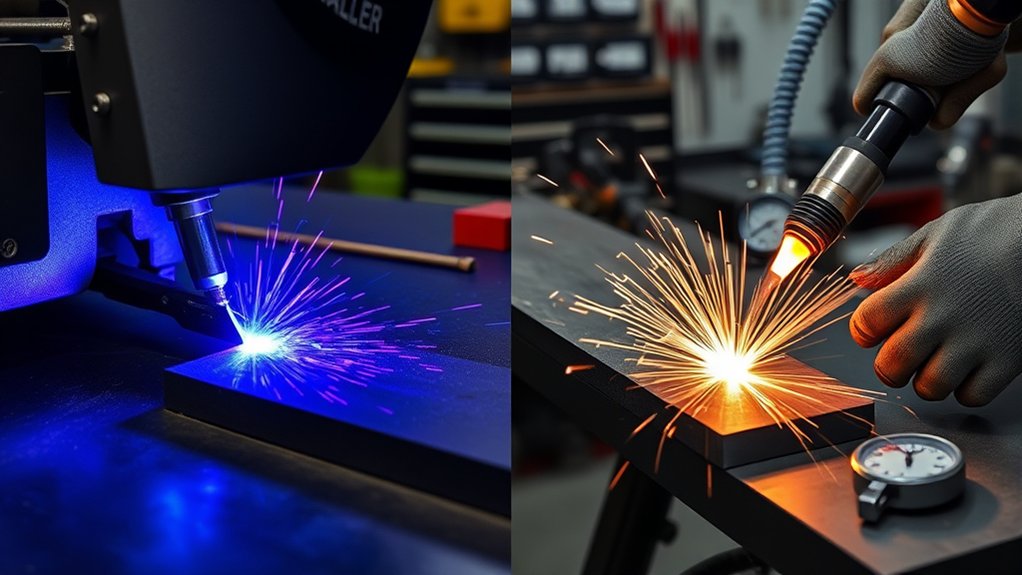

You’re weighing plasma cutting against oxy-acetylene for metal work, so focus on measurable differences: plasma delivers tighter kerfs, less taper, and faster cuts on most conductive metals, while oxy-acetylene excels on thick carbon steel and in remote, power-free settings. Upfront costs favor torches, but plasma often wins on operating efficiency and reduced rework. Safety also diverges: no open flame or fuel gases with plasma. The right choice hinges on your thickness range, duty cycle, and risk tolerance.

Overview of Cutting Methods

Although both processes cut metal thermally, they operate on different physics and suit different jobs.

With oxy-acetylene, you preheat ferrous steel using a fuel-oxygen flame, then inject pure oxygen to oxidize and blow out iron oxide. This cutting technique handles mild steel and wrought iron but won’t cut aluminum or stainless.

Plasma, by contrast, drives an electrically ionized arc through the workpiece, melting any conductive metal—steel, stainless, or aluminum—without oxidation.

Expect measurable differences. Plasma delivers faster travel on thin stock—steel at roughly 80 inches per minute—while oxy-acetylene runs slower due to preheat time.

Plasma’s kerf is tighter, about 1/16 to 1/8 inch, with smoother edges and minimal slag; oxy-acetylene typically yields 1/8 to 3/16 inch kerfs and more dross to remove.

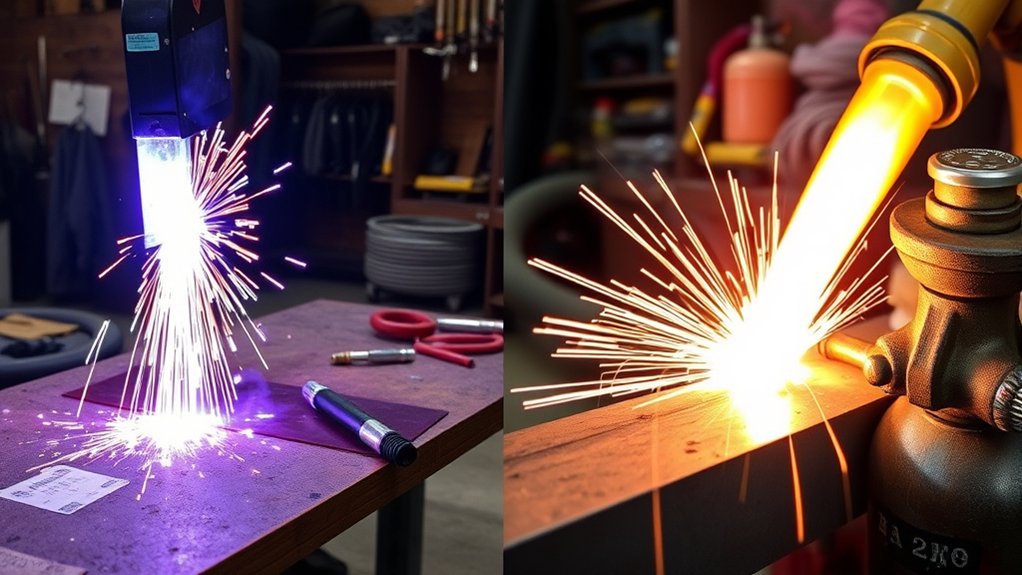

From a safety perspective, plasma avoids open flames and flammable gases, reducing explosion risk. Oxy-acetylene demands strict gas handling protocols.

Ongoing technology advancements continue improving precision, speed, and operator safety.

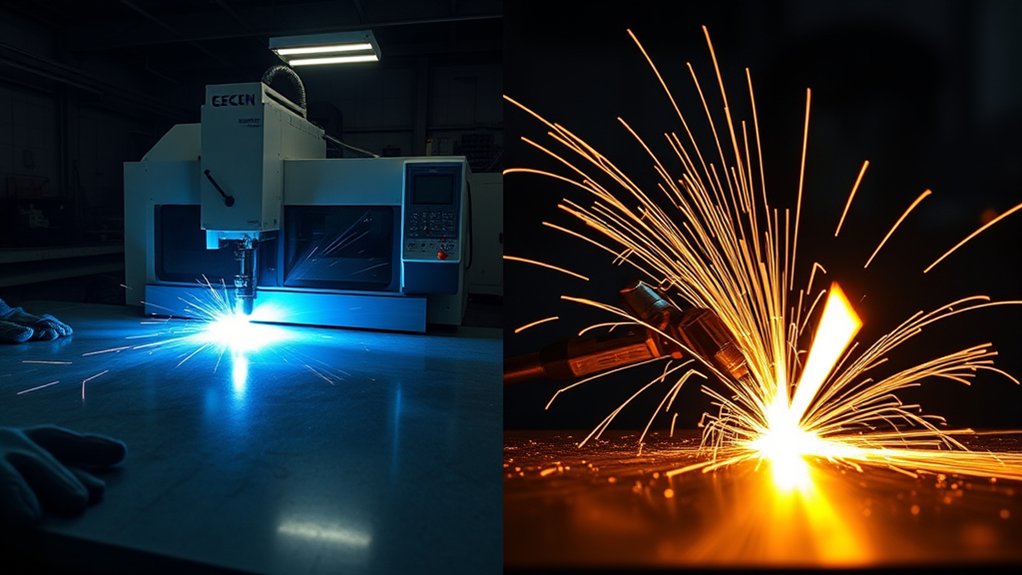

Plasma Cutting Basics

You’ll use a jet of ionized gas (plasma) that conducts electricity to arc through conductive metals, producing a narrow kerf and minimal slag without preheating.

Plan for stable power (typically 120–240 V, 20–50+ A output) and clean, dry compressed air around 90–120 psi at 4–7 scfm to cut efficiently up to roughly 1 inch.

For safety and performance, match amperage and air flow to material thickness and maintain proper grounding, dry air filtration, and correct torch standoff.

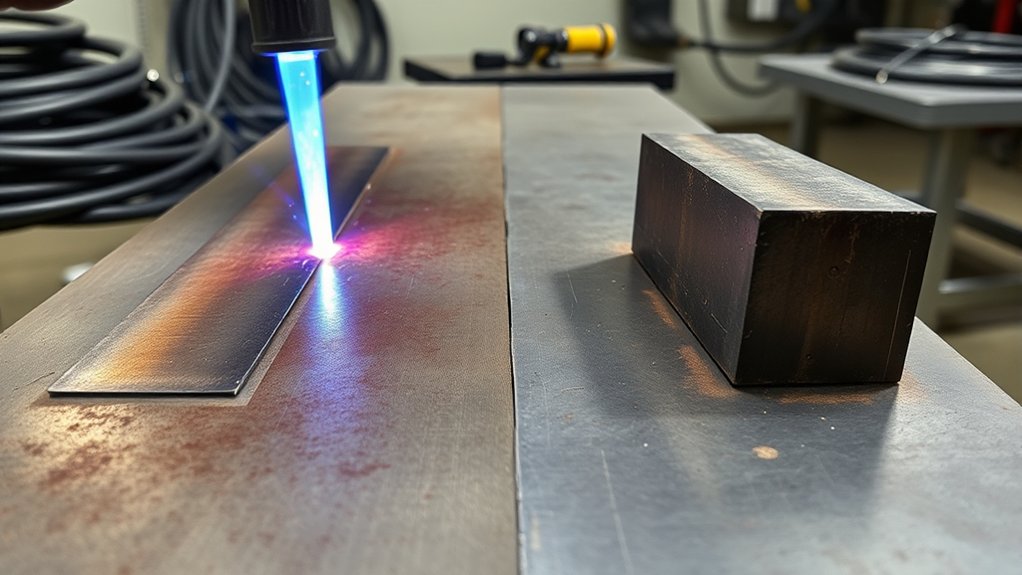

What Plasma Is

Plasma, an ionized gas that conducts electricity, is the working medium in plasma cutting. You create plasma through energy addition to a neutral gas—typically compressed air—until electrons free from atoms, turning it into a highly conductive jet. An electric arc forms between the torch electrode and the workpiece, constricting and accelerating the ionized gas to melt and eject metal. Because it’s an instantaneous process without preheating, you start cutting immediately, improving throughput and reducing heat input to surrounding material.

| Property | Why it matters | Safety note |

|---|---|---|

| Conductivity | Closes the arc circuit | Maintain dry leads |

| Temperature (~20,000°C) | Rapid melting | Use PPE, face shield |

| Jet velocity | Narrow kerf | Secure work, control standoff |

| Material range | Steel, stainless, aluminum, copper, bronze | Vent fumes, avoid coatings |

Typical capacity reaches about 1 inch; advanced systems exceed that.

Power and Air Requirements

Two essentials drive plasma cutting: electricity and compressed air. You’ll need a stable electrical source and a reliable air supply to sustain the arc and eject molten metal.

Power consumption varies by machine: compact units typically run 15–40 amps on 120V, while heavier-duty cutters require 220/240V and can draw 50–100 amps. Verify circuit capacity and use properly rated cords to avoid voltage drop, nuisance trips, and overheating.

Compressed air is the standard gas. Plan for clean, dry air at the manufacturer’s specified pressure and flow—often in the 4–7 SCFM range at 90–120 PSI. Use a dryer and filter to prevent arc instability and tip erosion.

Portable cutters, around 20 pounds, pair well with small compressors, simplifying setup versus multi-cylinder oxy-fuel systems.

Oxy-Acetylene Cutting Basics

Although simple in concept, oxy-acetylene cutting demands precision and strict safety control: you preheat ferrous metal to about 1,600°C (2,912°F) with an acetylene-oxygen flame, then trigger a high-velocity oxygen jet that oxidizes the hot steel and expels iron-oxide slag.

You’ll rely on this exothermic reaction for most oxy acetylene applications on mild steel and wrought iron; it won’t cut aluminum or stainless. Cutting rates are slower than plasma, especially on thick sections, so plan for longer passes and steady hand speed.

1) Gas setup: Use clean regulators, correct tip size, and leak-check hoses. Torch maintenance—tip cleaning, seat inspection, and O-ring replacement—prevents backfires and maintains stable preheat.

2) Flame tuning: Set a neutral flame for consistent preheat; avoid carburizing flames that hinder oxidation.

3) Preheat control: Reach bright-red heat uniformly before pressing the oxygen lever; maintain standoff to keep the kerf open.

4) Slag management: Follow the kerf with slight drag; chip residual iron oxide promptly to prevent heat buildup and re-ignition.

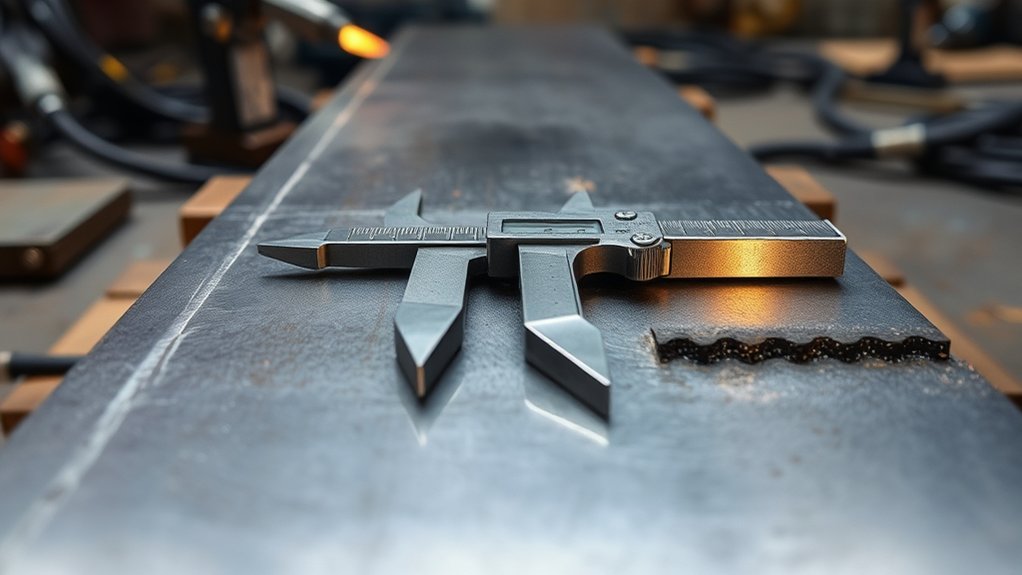

Cut Quality and Precision

Mastering flame tuning and preheat timing sets the stage for the next question: how clean and accurate your cuts can be. For cut quality and a precision comparison, plasma wins on most metrics. You’ll see narrower kerfs (1/16–1/8 in) and tighter tolerances (±0.010 in) versus oxy-acetylene’s wider kerfs (1/8–3/16 in), 2–5° taper, and larger HAZ. Plasma’s smaller heat-affected zone reduces thermal deformation and warping—critical on thin sheet. Edges are typically smoother with minimal slag, so you’ll spend less time on cleanup. Plasma also works on aluminum and stainless, where oxy-fuel can’t cut or can’t hold comparable precision.

| Metric | Implication |

|---|---|

| Kerf width | Plasma: narrow; oxy: wider, more material loss |

| Tolerance | Plasma ±0.010 in; oxy looser, dimensional drift |

| Edge finish | Plasma smooth; oxy rough, slag removal required |

| Taper | Plasma minimal; oxy 2–5° reduces accuracy |

| HAZ size | Plasma small (less warping); oxy larger (distortion risk) |

For safety and consistency, verify consumables, standoff, and gas quality before each cut.

Speed and Productivity

Because time on the torch is money, plasma cutting typically delivers far higher throughput than oxy‑acetylene, especially on thin to mid‑thickness stock.

You’ll see cutting efficiency translate directly into productivity gains when you eliminate preheat, shorten setup, and minimize rework.

– 1) Speed metrics: A 1/2-inch plate cuts at up to 80 in/min with plasma, while oxy‑acetylene commonly runs 8–10 in/min on 2-inch plate.

On thinner stock, plasma maintains higher traverse speeds with stable kerf and arc density.

– 2) Zero preheat: Plasma starts cold; no flame soak.

You avoid 3–5 minutes of gas tweaks and ignition, so your first arc strikes in under a minute.

- 3) Less rework: Cleaner edges and minimal dross reduce grinding passes and heat-affected distortion, improving downstream fit-up and weld prep.

- 4) Workflow reliability: Faster deployment and consistent travel speed enable tighter takt times, smoother scheduling, and safer operations by reducing torch-on time, hot work exposure, and operator fatigue.

Cost Breakdown: Upfront and Operating

Even before you strike an arc, costs diverge sharply: expect $500–$1,000 for an entry plasma unit versus $800–$1,200 for a pro-grade oxy‑acetylene rig, but day‑to‑day expenses flip the equation.

Your initial investment looks lower with oxy‑fuel at the top end, yet recurring operational costs dominate total ownership.

Upfront oxy‑fuel seems cheaper, but recurring operating costs drive true lifetime expense.

Plasma draws electricity and uses compressed air; you’ll budget mainly for consumables—electrodes and nozzles at $20–$100 per set—and power.

Oxy‑acetylene requires continuous oxygen and fuel refills plus tip maintenance and replacements, which lift operating spend over time.

In practice, plasma’s faster travel speeds and smaller heat‑affected zones shorten cycle time, cut rework, and reduce scrap, lowering labor and material overhead.

That efficiency offsets higher purchase price and power usage.

Quantitatively, if you cut regularly, plasma’s lower per‑cut cost and reduced post‑processing can surpass oxy‑fuel’s lower sticker.

If you cut infrequently, cylinder rental and refill minimums can make oxy‑acetylene comparatively costly per job.

Safety Considerations and Risks

While both processes can cut cleanly and fast, their risk profiles differ sharply and dictate distinct controls. Plasma cutting eliminates flammable gases and open flames, reducing explosion and burn potential; the arc self-extinguishes when you lift off.

Oxy‑acetylene adds hazards from pressurized cylinders, leaks, and sustained flame, demanding tighter controls and monitoring. Plasma also throws less slag and dross, lowering injury from hot debris. Conduct a task‑specific risk assessment before choosing a process.

- Accident prevention: Implement gas leak checks, leak‑down tests, and flashback arrestors for oxy‑acetylene; verify plasma torch interlocks and ground integrity. Use protective gear: ANSI Z87.1 shield, gloves, FR clothing, and hearing protection.

- Safety training: Certify operators on cylinder handling, regulator use, torch lighting/shutdown, arc hazards, and hot‑work permits.

- Equipment maintenance: Inspect hoses, regulators, and check valves; for plasma, maintain consumables, leads, filters, and duty cycle limits.

- Emergency protocols: Stage Class B/C extinguishers, purge and isolate gas, ventilate, and establish shutdown and first‑aid responses for burns, shocks, and eye injuries.

Portability and Power Requirements

Although both processes travel to the work, their logistics differ sharply: compact inverter plasma cutters (often ~20 lb) move easily and set up in under a minute, but they demand electricity and compressed air—ranging from 120V at 15–40 A for small units to 220/240V drawing 50–100 A for higher output. Oxy‑acetylene brings heavier cylinders, regulators, and hoses; it’s slower to set up, yet it’s independent of grid power, which matters off‑grid.

For portability considerations, you’ll weigh corded demands versus cylinder mass and transport safety. Plasma wins for quick, light moves; oxy‑fuel wins where electricity and air aren’t available. Evaluate power efficiency by matching duty cycle and amperage to your circuit capacity and generator rating.

| Factor | Practical Implication |

|---|---|

| Weight/Footprint | Plasma ~20 lb units vs. cylinder-based oxy‑fuel rigs |

| Power/Utilities | Plasma: electricity + clean dry air; Oxy‑fuel: gas bottles only |

| Setup/Deployment | Plasma: <1 min; Oxy‑fuel: slower—pressure set, leak checks, ignition |

Choosing the Right Tool for Your Metals and Thicknesses

You’ll match the tool to your metal first: use plasma for aluminum, stainless, and thin-to-mid steel with 1/16–1/8 in kerfs; choose oxy-acetylene only for ferrous steels where wider 1/8–3/16 in kerfs and slag are acceptable.

For thickness, run plasma efficiently up to ~1 in, but switch to oxy-fuel for heavy plate and structural work approaching 300 mm.

In the field vs shop, balance power and safety—plasma avoids open flames and suits controlled shop setups, while oxy-fuel’s lower upfront cost and portability can favor remote jobs with proper gas handling protocols.

Metal Type Compatibility

Before striking an arc or lighting a torch, match the tool to the metal and thickness: plasma cutters handle any electrically conductive material—aluminum, stainless, copper, and steels—with a narrow 1/16–1/8 in kerf, no preheat, and high precision on thin sheet and intricate profiles.

You’ll align material properties with cutting applications more reliably when you separate processes by chemistry and oxidation behavior. Oxy-acetylene relies on iron’s exothermic reaction, so it’s limited to ferrous metals.

- Use plasma for aluminum and stainless; oxy-fuel can’t oxidize them effectively.

- Choose plasma for mixed-metal jobs; switch metals fast without preheating.

- Favor plasma’s tighter kerf for minimal waste and accurate fit-up.

- Select oxy-fuel only for ferrous sections where oxidation assists the cut and consumables are on hand.

Thickness Range Sweet Spots

When thickness dictates the cut, match process to the sweet spot: use plasma on thin to medium stock for speed, precision, and low heat input, and reserve oxy‑acetylene for heavy ferrous sections where oxidation carries the cut.

You’ll see clear thickness limitations and ideal applications. For sheet to 1/8 inch, plasma minimizes distortion and HAZ while maximizing throughput.

On 1/2‑inch steel, plasma routinely hits about 80 inches per minute; oxy-fuel is slower and needs preheat. Plasma stays efficient up to roughly 1 inch across steels, stainless, and aluminum.

Beyond that, oxy‑acetylene takes over on ferrous plate, scaling to about 300 mm with proper tip, preheat, and travel speed.

Choose plasma for mixed alloys and varying gauges; pick oxy-fuel when sections are thick, straight, and carbon‑steel.

Field Vs Shop Setup

Although both processes can live in the truck and on the bench, field vs shop setup hinges on portability, setup time, cut quality, and the metal you’re tackling.

In field applications, a 20 lb inverter plasma with a 1/16–1/8 in kerf, minimal dross, and sub-60-second startup beats hauling cylinders, regulators, and hoses.

In shop environments, plasma still wins on precision and edge quality, while oxy-acetylene retains value for very thick ferrous plate where heat input is acceptable.

- Portability: Plasma (~20 lb) vs oxy-acetylene (cylinders/regulators); safer transport and faster deployment.

- Setup time: Plasma <1 minute; oxy-acetylene 3–5 minutes, plus leak checks and purges.

- Cut quality: Plasma yields smoother edges, smaller HAZ; oxy-acetylene risks warping thin stock.

- Material match: Plasma favors thin/non-ferrous; oxy-acetylene for heavy ferrous sections.

Frequently Asked Questions

How Do Weather Conditions Affect Outdoor Plasma or Oxy-Acetylene Cutting?

Weather conditions alter cut stability and safety. You mitigate wind effects by shielding arcs/torches; wind blows plasma jets and flames, degrading kerf quality. You manage humidity impact by drying air, preventing hydrogen porosity, electrical tracking, and tip freeze. Wear PPE; verify grounding; monitor gas pressures.

What Accessories Improve Cut Quality and Workflow for Each Method?

You sharpen the blade’s shadow with cutting accessories and workflow enhancements. For plasma, use fine-cut nozzles, drag shields, CNC guides, air dryers, and PPE. For oxy-fuel, select correct tips, preheat indicators, flashback arrestors, tip cleaners, and precise pressure regulators.

How Loud Are These Tools, and Are Hearing Protections Required?

They’re loud. You’ll encounter noise levels around 95–110 dBA for plasma and 85–100 dBA for oxy‑acetylene. You should wear hearing protection: at least NRR 25–30 earmuffs; add earplugs for prolonged cutting or confined spaces.

Can Either Method Be Used for Artistic Engraving or Etching?

Yes—but you’ll sketch with lightning, not a pen. For artistic applications, plasma excels at shallow reliefs; oxy-fuel suits texture marking. Use stencils, CNC guidance, controlled amperage/oxygen flow, precise torch angles. Prioritize PPE, ventilation, fire control, and post-process finishing.

What Are Common Beginner Mistakes and Quick Troubleshooting Tips?

Common beginner errors include misaligned standoff, wrong tip size, dirty ground, excessive travel speed, and inadequate PPE. Apply troubleshooting techniques: verify amperage, check gas flow/pressure, inspect consumables, clean connections, calibrate torch height, slow feed, practice straight cuts, and enforce ventilation/fire-watch.

Conclusion

You’ve seen the numbers and the nuances. If cut quality, narrow kerf, and minimal taper are your North Star, a plasma cutter slices like a laser through fog—fast, precise, and safer without open flames or fuel gases. Oxy-acetylene still shines for thick plate and field repairs, but it’s a heavier lift in hazards and upkeep. Weigh upfront cost against duty cycle, consumables, power needs, and metal type. Choose the tool that makes your workflow hum—and keeps your crew safe.