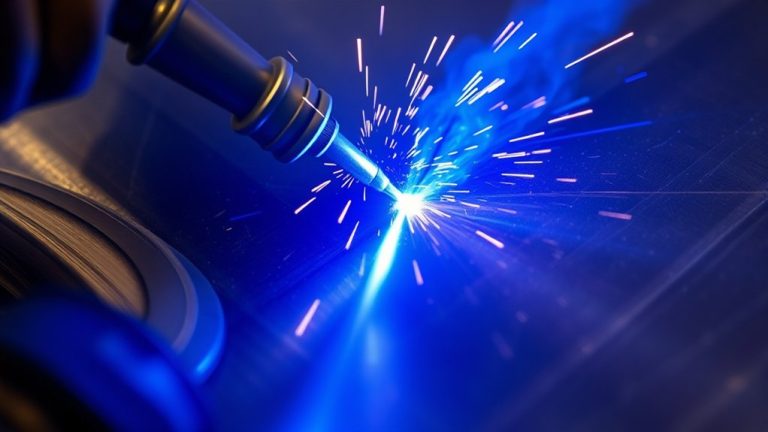

When you aim for high plasma cutting quality, focusing on edge finish and dross control is essential. Start by selecting the correct CNC plasma cutter settings, considering factors like cutting speed and amperage. Make certain the torch is properly aligned and squared to prevent uneven edges and excessive consumable wear. Regularly inspect your consumables and adjust your torch-to-work distance accordingly. Understanding these elements will greatly enhance your cutting results, but there’s more you need to know.

Plasma Arc Direction and Its Impact on Cut Quality

When considering plasma cutting, understanding the direction of the plasma arc is crucial for achieving high-quality cuts. Arc stability is paramount, as the arc typically rotates clockwise during standard operations, creating square cut edges on the right side.

For internal features, you must direct the torch counterclockwise to maintain edge integrity. These directional adjustments are essential to guarantee ideal cut quality and minimize dross formation.

Precise torch alignment with the workpiece is critical. Aligning correctly prevents uneven cuts and achieves the desired edge finish.

The relationship between gas flow and plasma arc direction shouldn’t be overlooked—correct pressure and flow rates considerably enhance the cleanliness and smoothness of cut edges.

By mastering these directional nuances, you’re empowered to produce superior cuts that embody precision and efficiency, liberating you from the constraints of inadequate cutting practices.

Achieve mastery and elevate your plasma cutting techniques to new levels of excellence.

Selecting the Correct CNC Plasma Cutter Settings

When you’re selecting the correct CNC plasma cutter settings, pay close attention to the ideal speed and material thickness to guarantee high-quality cuts.

Refer to the Hypertherm Instruction Manual‘s cut charts for precise recommendations, and remember that adjusting cutting speed is critical to avoid dross build-up and achieve smooth edges.

Balancing lower amperage settings with the appropriate speed will enhance angularity and edge quality, especially for varying material thicknesses.

Optimal Speed Selection

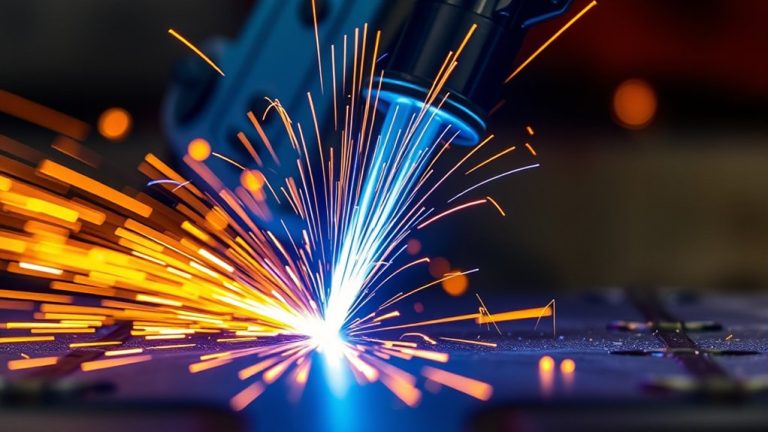

Selecting the ideal cutting speed is vital for achieving precise and clean cuts with a CNC plasma cutter, as it directly influences edge quality and dross formation.

When dealing with cutting materials, understanding speed variations is significant. A balance between high and low speeds creates a “dross-free window” that varies depending on plasma gas and material type.

Too fast results in high-speed dross, while too slow causes low-speed dross. For carbon steel, oxygen plasma gas provides a broader dross-free window compared to nitrogen or air.

Conduct test cuts to identify the best speed for your specific material. Maintain the correct torch height alongside the chosen speed to guarantee consistent, high-quality edges and minimal dross accumulation.

Material Thickness Considerations

Understanding the nuances of material thickness is essential when adjusting CNC plasma cutter settings for ideal results. Achieving superior cut quality requires precise calibration. Here’s how you can master it:

- Adjust Speed and Amperage: For material thickness over 0.5 inches, increase amperage and reduce speed to maintain clean edges.

- Select the Right Plasma Gas: Use oxygen for materials thicker than 0.375 inches to enhance speed and cleanliness; nitrogen is better for thinner stainless steel.

- Consult Cut Charts: Refer to the Hypertherm Instruction Manual for exact settings tailored to your material’s type and thickness.

- Monitor Consumables: Regularly inspect and replace consumables to prevent wear that degrades cut quality and increases dross formation.

Embrace these strategies for freedom in creating flawless cuts.

Evaluating and Replacing Worn Plasma Consumables

Regular inspection of plasma consumables like nozzles and electrodes is essential to guarantee peak cutting quality and minimize dross formation.

Carefully monitor wear indicators such as misaligned arcs or inconsistent cut edges. These signs dictate the replacement frequency to ensure maximum performance. Always replace both the nozzle and electrode simultaneously, as partial replacements can lead to imbalanced wear and compromised results.

Monitor wear indicators closely; replace both nozzle and electrode together for optimal performance and balanced wear.

Utilize genuine Hypertherm consumables—they’re engineered for compatibility, guaranteeing stability and precision.

Over-lubricating O-rings can disrupt plasma gas flow, so follow manufacturer guidelines to avoid improper sealing. Neglecting consumable maintenance leads to poor cut quality and excessive dross, hindering your operational efficiency.

Ensuring Proper Torch Alignment and Squaring

To guarantee precise square cuts, you must prioritize leveling the workpiece, as any deviation can compromise torch alignment and cutting accuracy.

Confirm the torch’s stability in its mount to prevent shifts during operation, which could affect cut integrity.

Address any material warping by securing the workpiece flat on the cutting table, as irregularities can disrupt the torch’s path and result in inferior cut quality.

Leveling Workpiece Importance

Although often overlooked, leveling the workpiece is essential for guaranteeing proper torch alignment and squaring during plasma cutting.

Confirming workpiece flatness guarantees consistent cutting height, enhancing cutting precision and minimizing angularity issues.

Here’s how you can achieve this:

- Check Flatness: Use a precision level to confirm the workpiece is flat, eliminating warping that could disrupt torch height.

- Secure Properly: Firmly attach the workpiece to the cutting table to prevent movement, reducing inaccuracies.

- Align Torch: Verify the torch is square from both the front and side, allowing the plasma arc to be perpendicular for cleaner cuts.

- Regular Calibration: Periodically check and adjust the torch alignment relative to the leveled workpiece, maintaining ideal cutting conditions and extending consumable life.

Liberate your process with precision.

Torch Mounting Stability

Guaranteeing torch mounting stability is crucial for achieving precision in plasma cutting. When the torch is securely mounted, you minimize vibrations, leading to more consistent cuts and superior edge quality.

Torch security begins with effective mounting techniques: align the torch so it’s squared to the workpiece from both the front and side. This alignment guarantees precise interaction between torch and material.

Leveling the workpiece before starting the cut prevents inaccuracies, maintaining a consistent torch height. Regular maintenance and calibration of both the torch and cutting table are critical. They not only enhance cutting performance but also extend the lifespan of your consumables.

Material Warping Effects

When cutting with plasma, precise torch alignment plays a pivotal role in preventing material warping, a common issue that can compromise the integrity of your workpiece.

Proper alignment guarantees consistent cutting angles, counteracting the effects of thermal expansion on material properties. To maintain precision, follow these steps:

- Square Alignment: Confirm the torch is square to the workpiece from both front and side to prevent uneven cuts.

- Level Surface: Level the workpiece before cutting; any tilt can exacerbate warping and affect edge quality.

- Material Correction: Correct any warped or bent materials beforehand, as they disrupt the torch’s path.

- Secure Mounting: Regularly check the torch’s secure mounting to guarantee stability and minimize fluctuations.

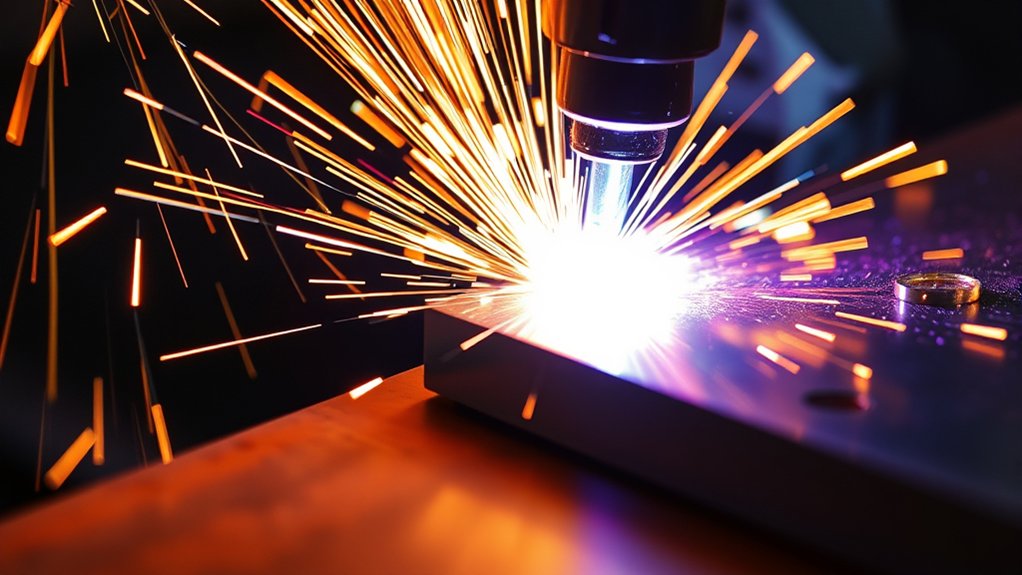

Importance of Torch-to-Work Distance

To achieve superior plasma cutting quality, mastering the torch-to-work distance is crucial. By implementing precise torch calibration techniques, you guarantee ideal arc stability and consistent cutting performance. The recommended distance, typically between 1/16 and 1/8 inch, is essential for maintaining clean edges and minimizing dross formation.

Incorrect torch distances can cause poor cuts and increased wear on consumables, so employing effective distance adjustment methods is critical.

Consistent torch height is your ally in preventing arc instability and guaranteeing uniform cutting speeds, which directly influences edge quality. Automatic height control systems offer a sophisticated solution, allowing real-time adjustments that enhance cutting conditions.

These systems adapt to material type, thickness, and specific cutting parameters, providing the flexibility needed for high-quality results. Always consult manufacturer specifications and perform test cuts to determine the ideal torch-to-work distance for your specific application, liberating you from potential cutting inconsistencies.

Adjusting Cutting Speed for Optimal Performance

Achieving ideal performance in plasma cutting hinges on meticulously adjusting the cutting speed. It’s crucial to balance speed to minimize dross formation and achieve superior edge quality.

Here’s how you can refine your technique:

- Test Cuts: Conduct test cuts at varying speeds. This helps you pinpoint the best cutting speed that minimizes dross and yields a clean edge.

- Material Thickness: Calibrate the cutting speed based on material thickness. Remember, thicker materials generally necessitate slower speeds to avoid excessive dross formation.

- Dross-Free Window: Identify your dross-free window, which fluctuates depending on the plasma gas. Oxygen, for example, offers a wider window than nitrogen or air, enhancing versatility.

- Arc Angle Monitoring: Regularly check the arc angle during cutting. If the arc is too steep or shallow, adjust the speed accordingly to perfect the edge finish.

Mastering these elements liberates you from subpar cuts, empowering precision and efficiency in your plasma cutting endeavors.

Addressing Gas Delivery System Issues

While adjusting cutting speed plays a pivotal role in enhancing plasma cutting quality, ensuring an efficient gas delivery system is equally imperative for achieving precision.

Begin with a meticulous gas leak inspection—any minor leaks can disrupt plasma flow, leading to inconsistent cuts. Next, regularly monitor pressure regulation to align with the Hypertherm Instruction Manual. Inaccurate pressure levels can severely affect cutting performance, resulting in subpar edge finishes.

Choose high-quality, pure gases to avoid arc instability and excessive dross formation. Impurities in gases undermine the stability of the plasma arc, compromising cut quality.

Inspect all gas lines and fittings for wear or damage, as faulty components hinder plasma and shielding gas delivery, leading to uneven cuts. Implement routine maintenance checks on your gas delivery system, ensuring it functions effectively.

This diligence liberates your cutting process, allowing for ideal speeds and superior edge quality in every cut.

Minimizing Torch Vibration and Its Effects

Though often overlooked, minimizing torch vibration is vital for maintaining the precision and quality of plasma cutting operations. Torch vibration sources can lead to rough surfaces and jagged cuts, especially in thinner materials.

Minimizing torch vibration is crucial for precision and quality in plasma cutting, preventing rough surfaces and jagged cuts.

To address these issues, consider implementing the following vibration dampening techniques:

- Secure Mounting: Regularly check and tighten the torch mount to guarantee stability. Loose mounts are a primary source of vibration, affecting arc stability and cut accuracy.

- Optimize Cutting Speed: Adjust your cutting speed to match the material thickness. Too fast or too slow speeds can magnify vibrations, leading to imprecise cuts and increased dross.

- Consistent Torch Height: Maintain a steady torch height throughout the cutting process to minimize arc drift and enhance cut precision.

- Advanced Motion Control: Incorporate motion control technologies to stabilize the arc, reducing the adverse effects of vibration and guaranteeing a smooth edge finish.

Liberate your operations by mastering these techniques, guaranteeing precision and quality in every cut.

Tuning the Plasma Cutting Table for Better Results

When optimizing your plasma cutting table for superior results, understanding the interplay of key factors like gas flow, pressure, and cutting speed is vital.

Start by ensuring your plasma table calibration is spot on. Regularly inspect and replace worn consumables such as nozzles and electrodes. This practice not only enhances edge finish optimization but also minimizes dross.

Correct gas flow and pressure settings enable shiny, glassy edges with minimal rounding. Adjust cutting speed according to material type and thickness—high-speed dross indicates excessive speed, while low-speed dross suggests the opposite.

An automatic height control system is indispensable for maintaining consistent torch-to-workpiece distance, thereby ensuring uniform cut quality.

Regular maintenance and calibration of your plasma cutting setup are essential. They prevent issues like uneven edges, liberating you from the constraints of subpar performance and allowing you to achieve precise, professional-quality cuts every time.

Frequently Asked Questions

How Does Material Thickness Affect Dross Formation?

Material thickness directly impacts dross formation by influencing cutting speed and heat distribution. Thicker materials require slower speeds, increasing dross risk. Consider material type, since different compositions react uniquely. Fine-tune settings for ideal results and minimal cleanup.

What Role Does Amperage Play in Edge Finish Quality?

Adjusting amperage is essential for edge refinement. You must optimize it to balance penetration and smoothness, ensuring precise cuts. A higher amperage can reduce dross but risks rough edges, whereas lower amperage might improve finish but decrease efficiency.

Can Environmental Conditions Influence Plasma Cutting Results?

Yes, environmental conditions can influence plasma cutting results. Temperature fluctuations and humidity levels impact arc stability and material conductivity. Guarantee consistent conditions to achieve precise cuts, liberating you from inconsistent results and enhancing overall cutting performance and efficiency.

How Do Different Gases Impact Dross Control?

Using oxygen as a cutting gas can reduce dross by up to 50%. Different gas types like nitrogen and air influence cutting speed and precision, offering you the freedom to tailor processes to specific material properties and project goals.

What Is the Effect of Electrode Wear on Cutting Efficiency?

Electrode wear drastically reduces cutting precision and efficiency, as it shortens electrode lifespan. You’ll notice increased arc instability and inconsistent cuts. Regularly replacing electrodes guarantees peak performance and liberates you from time-consuming errors and costly rework.

Conclusion

In mastering plasma cutting, remember that precise adjustments lead to superior results. Did you know that a mere 10% increase in cutting speed can greatly reduce dross formation? This highlights the critical nature of dialing in ideal settings. Confirm your torch is perfectly aligned and at the correct distance to prevent uneven edges. Regularly inspect and replace worn consumables, and address any gas delivery issues. By minimizing torch vibration and tuning your cutting table, you’ll achieve cleaner, sharper cuts every time.