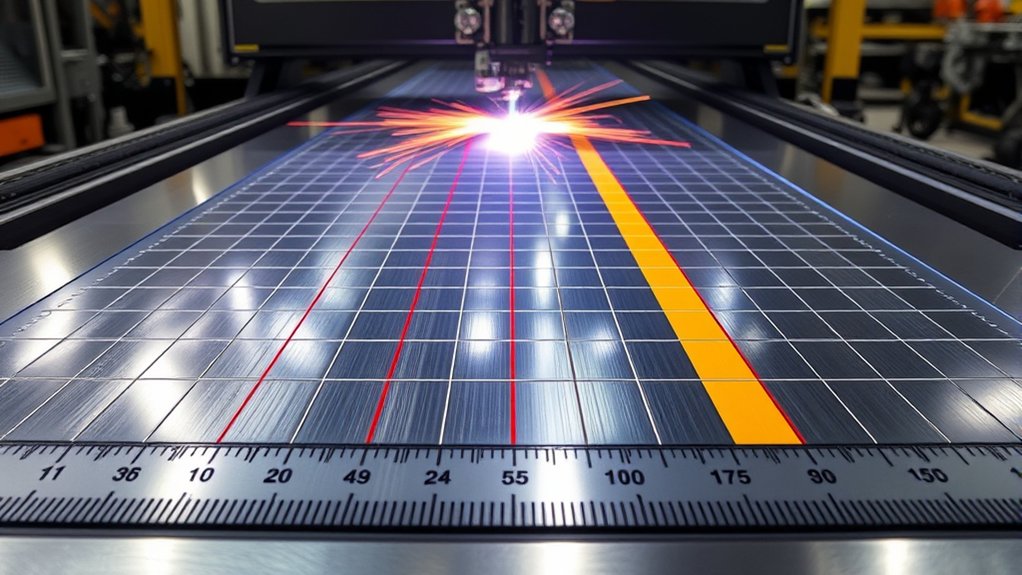

Did you know that using the wrong amperage for a specific material thickness can drastically affect your cut’s quality? The plasma cutting speed chart is essential for aligning material thickness with proper amperage and cutting speed, whether in inches per minute (IPM) or millimeters per minute (mm). This guarantees precision and efficiency in your cuts. Understanding this chart could be the key to refining your plasma cutting operations. Curious about improving your cuts?

Understanding the Plasma Cutting Speed Chart

When you explore the plasma cutting speed chart, you’ll quickly realize its crucial role in enhancing your cutting operations. This chart isn’t just a guide; it’s your pathway to achieving superior cut quality.

By aligning your material’s thickness with the appropriate amperage, you can maintain precision and efficiency. For instance, a 40 amp tip on 14 gauge steel at 50 IPM guarantees a clean edge with minimal distortion.

The chart is indispensable for managing kerf width, which is important for compensating material loss. Consistent standoff distance is emphasized to prevent angular cuts, maintaining uniformity throughout your project.

Managing kerf width is vital for compensating material loss and ensuring uniformity in your cutting projects.

As you increase amperage, you’ll notice a significant boost in cutting speed, especially with thicker materials. However, staying within the recommended parameters guarantees that you don’t compromise on cut quality.

Mastering these elements liberates you from the confines of guesswork, empowering you to achieve ideal results.

Factors Influencing Cutting Speed

Understanding the factors influencing cutting speed in plasma cutting is fundamental to optimizing performance and achieving high-quality results. When you dial in the cutting speed, you’re balancing precision and efficiency.

Too fast, and you risk arc stability issues and excessive dross; too slow, and you may face wide cuts and material distortion. The key is finding that sweet spot where the arc stability is maintained, ensuring clean cuts and minimal material waste.

Consider these vital elements:

- Material thickness: Your cutting speed should align with the material’s thickness. For instance, a Hypertherm Powermax 85 SYNC can manage 200 IPM on 1/4-inch material.

- Amperage settings: Higher amperage boosts cutting speed, but it’s essential to match it with the material thickness to maintain quality.

- Standoff distance: Keep this consistent. Variations can affect arc voltage, which in turn influences cutting speed and cut quality.

Master these factors, and you’ll reveal the true potential of plasma cutting.

Optimal Amperage Settings for Different Thicknesses

To achieve ideal cutting results, you need to carefully select the appropriate amperage settings based on material thickness, ensuring a balance between efficiency and quality.

For instance, a 40 amp tip is ideal for cutting 14 gauge metal, while a 50 amp tip suits materials up to 1/4 inch thick, effectively correlating thickness with amperage.

Amperage Selection Guidelines

Selecting the correct amperage settings is vital for achieving ideal cutting performance in plasma cutting operations. To harness superior performance, you must focus on precise amperage adjustments tailored to material thickness.

Consider the following:

- 14 gauge material: A 40 amp tip strikes a balance, enhancing speed and quality.

- Thin materials (up to 0.6mm): A 20 amp tip minimizes excessive dross and distortion.

- Heavier materials (up to 1.0mm): Opt for a 50 amp tip to maintain cutting efficiency.

Testing different amperage settings on your specific material is essential. Performance varies with material type and thickness, demanding a personalized approach.

Thickness-Amperage Correlation

Having established the importance of amperage selection, let’s explore the correlation between material thickness and ideal amperage settings.

Precision in cutting techniques starts with meticulous material selection and matching the amperage to your material’s thickness. For 14 gauge material, a 40 amp tip strikes the perfect balance, preventing distortion and ensuring quality cuts.

When dealing with thinner materials, a 20 amp tip handles up to 0.6mm effortlessly, while 50 amps cut through 1.0mm with precision. Remember, a 30 amp setting is best for 0.8mm, and 40 amps for 0.9mm.

Avoid over-stressing your tips above their rated amperage, as this accelerates wear. Testing different settings enhances cut quality, especially for intricate applications, liberating you to achieve excellence in every cut.

Efficiency Through Amperage

While mastering plasma cutting efficiency, understanding ideal amperage settings for various material thicknesses is essential. You need to match optimal amperage with material thickness for superior cutting efficiency and precision.

Amperage balancing is key to preventing distortion or ineffective cuts:

- Use 20 amp tips for materials up to 15-20 amps, ensuring precise cuts without overloading.

- For 14 gauge materials, 40 amp tips are recommended to enhance performance and prolong tip life.

- With 1/4-inch steel, 50 amp tips offer efficient cutting, while 85 amps boost speed to 200 IPM.

Always consult amperage charts, like Hypertherm’s, to determine the correct power output.

Balancing speed and amperage is vital for avoiding slow cutting issues and maximizing efficiency in your projects.

Plasma Cutting Techniques for Precision

To achieve precision in plasma cutting, it’s crucial to set the ideal cutting speeds; too fast can result in arc instability and excessive dross, whereas too slow can lead to wide cuts and material distortion. Mastering cutting techniques involves precision adjustments across several parameters. For thin metal sheets, you should fine-tune your amperage output. Utilizing FineCut consumables creates a narrow kerf and a stiff arc, enhancing cut quality. Adjust the arc voltage to maintain a consistent standoff distance, as variations impact angularity and cut quality.

| Parameter | Ideal Setting | Effect on Precision |

|---|---|---|

| Amperage | Adjust for thickness | Narrow kerf, stiff arc |

| Arc Voltage | Consistent standoff | Improved angularity |

| Pierce Height | 1.5-2 times cut height | Reduces consumable wear |

| Kerf Compensation | Adjust to minimize waste | Enhances part accuracy |

Correct pierce height and effective kerf width compensation further guarantee quality by minimizing wear and improving accuracy.

Safety Considerations in Plasma Cutting

When you’re engaged in plasma cutting, prioritizing safety is non-negotiable due to the inherent risks of the process.

Equip yourself with appropriate PPE, such as heat-resistant gloves and safety glasses, to mitigate burn risk from high temperatures and sharp edges.

Additionally, guarantee proper grounding of your equipment to prevent electrocution, and always handle recently cut parts with caution to avoid thermal injuries.

Personal Protective Equipment

Ensuring safety during plasma cutting operations involves a thorough understanding of appropriate personal protective equipment (PPE) tailored for the task. Mastering PPE selection is vital for injury prevention, offering workers the freedom to operate efficiently without compromising safety.

Essential gear includes:

- Heavy-duty gloves: These prevent lacerations and burns, imperative when working with sharp and hot metal.

- Safety glasses: Protect your vision from sparks and harmful UV radiation emitted during cutting.

- Heat-resistant boots: Shield your feet against hot metal debris, ensuring stability and safety.

Reinforced apparel, like long-sleeved shirts and overalls, guards against intense heat.

With high energy outputs, such as the Hypertherm Python 125’s 175V, PPE becomes indispensable to mitigate electrocution risks, promoting a secure work environment.

Handling Hot Cut Parts

Despite the precision and efficiency plasma cutting offers, handling hot cut parts requires meticulous attention to safety protocols.

Hot metal handling is critical; recently cut parts can reach extreme temperatures, necessitating heat-resistant gloves to prevent burns. Direct skin contact with hot edges is a hazard, posing risks of serious lacerations or burns.

Temperature management is paramount—always utilize appropriate tools to maneuver freshly severed components. Reinforced boots are essential to shield your feet from potential injuries due to falling hot metal.

Large plate handling safety protocols should be adhered to, especially when dealing with thick plates, to avoid accidents from heavy lifting.

Finally, safety glasses are indispensable to protect your eyes from sparks and debris in the plasma cutting environment.

Electrical Safety Measures

Although plasma cutting is an efficient technology, it demands strict adherence to electrical safety measures due to the high voltage involved. With machines like the Hypertherm Python 125 outputting 175V, understanding and mitigating electrical hazards is crucial.

Follow these safety protocols to guarantee a secure working environment:

- Wear Proper PPE: Heavy-duty gloves, safety glasses, and reinforced boots are non-negotiable to protect against electrocution risks and lacerations.

- Guarantee Equipment Integrity: Regularly maintain your plasma cutter to prevent electrical failures. A malfunction can lead to severe injuries or worse.

- Maintain a Clean Workspace: Keep air supplies clean, dry, and oil-free. This prevents equipment malfunction, enhancing both performance and safety.

Your mastery over these protocols guarantees not only safety but also empowers efficient cutting operations.

Enhancing Performance With Beacon-Powered Systems

When you’re looking to boost your plasma cutting performance, Beacon-powered systems are a game changer. Their beacon technology guarantees cutting consistency by automatically adjusting voltage and torch distance for ideal standoff. This precise control over cutting parameters minimizes distortion and enhances cut quality. Achieving speeds over 100 IPM, Beacon systems greatly enhance production efficiency, liberating you from the constraints of manual adjustments.

| Feature | Benefit |

|---|---|

| Automatic Voltage Adjust | Maintains ideal arc voltage |

| Torch Distance Control | Guarantees consistent standoff |

| Speed Over 100 IPM | Enhances production efficiency |

| Real-Time Adjustments | Reduces heat input and distortion |

With the app’s real-time adjustments, you maintain the ideal arc voltage, vital for shaping clean cuts across various materials. This minimizes material distortion and improves the plasma cutting process, offering liberation from inefficient methods. By adopting Beacon-powered systems, you guarantee precision and efficiency, revolutionizing your cutting operations.

Frequently Asked Questions

What Is the Lifespan of a Plasma Cutting Machine?

Your plasma cutting machine’s lifespan depends on factors like usage frequency, maintenance, and operating conditions. Proper care and regular servicing enhance machine longevity, ensuring peak performance and freeing you from downtime constraints. Embrace this liberation with informed maintenance practices.

How Do Environmental Conditions Affect Cutting Speed?

Environmental conditions directly affect cutting speed. High humidity reduces cutting efficiency, while low atmospheric pressure can cause arc instability. You’ll need ideal conditions to guarantee precision and freedom from interruptions, allowing you to maximize productivity and machine lifespan.

Can Plasma Cutters Be Used Underwater?

Yes, you can use plasma cutters underwater, but prioritize safety considerations. Underwater applications require specialized equipment, ensuring electrical insulation and preventing gas leakage. Employ experienced operators and rigorous protocols to mitigate risks and achieve ideal precision and efficiency.

What Maintenance Is Required for Optimal Machine Performance?

Guarantee peak machine performance by conducting preventive maintenance. Regular inspection of consumables, torch alignment, and air filters is essential. Monitor for wear and replace parts proactively, guaranteeing peak efficiency and avoiding unexpected downtime, liberating you from costly repairs.

How Do Plasma Cutters Compare to Laser Cutters in Speed?

Plasma cutters typically offer faster speeds than laser cutters, especially on thicker materials. You’ll benefit from plasma’s advantages like rapid cutting and lower initial costs, overcoming laser’s disadvantages of slower processing on thicker metals and higher maintenance.

Conclusion

Mastering the plasma cutting speed chart is your ultimate ticket to cutting nirvana, where precision meets efficiency in a dance of sparks and steel. By harnessing the perfect blend of amperage, material thickness, and cutting speed, you’ll achieve cuts so flawless they’ll make a micrometer weep with envy. Embrace the symphony of technical prowess and safety protocols, and you’ll elevate your plasma cutting game to legendary status, leaving lesser operators in the dust of mediocrity.