When exploring plasma cutting technology, you’ll find it essential to grasp the nuances of various systems like air plasma, conventional, and high-precision options. Each system has its unique strengths, tailored for different material thicknesses and applications. The power source you choose directly affects your cutting speed and quality, with air plasma being cost-effective but susceptible to oxidation. So, how do you achieve ideal results? Consider the gas choice, torch distance, and advanced CNC systems.

Understanding Plasma Cutting: Basics and Mechanism

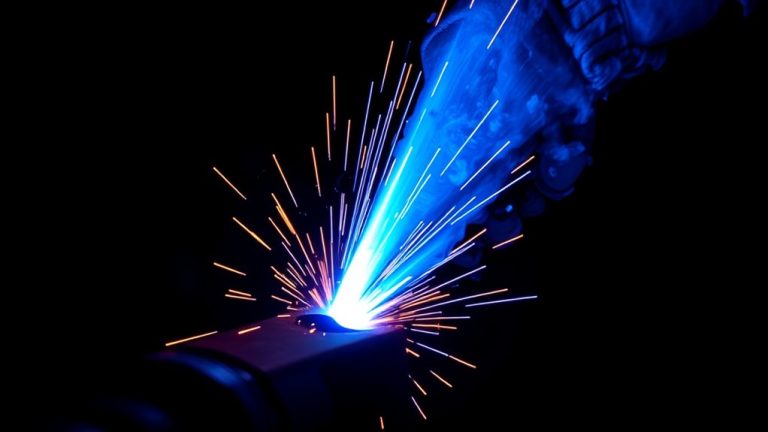

To grasp the fundamentals of plasma cutting, you need to understand the mechanics behind this high-precision process. Plasma cutting employs a plasma arc to slice through electrically conductive materials by utilizing an ionized gas, known as plasma—the fourth state of matter.

This cutting process initiates with a pilot arc, where high voltage ionizes the gas, transforming it into a powerful plasma stream. The plasma torch, equipped with a swirl ring, guarantees optimal cutting quality by maintaining a precise distance from the workpiece.

Compressed air, along with other gases like oxygen and nitrogen, plays a significant role in this process. These gases impact cutting speed, edge quality, and potential oxidation.

The plasma reaches temperatures up to 40,000°F, efficiently melting and blowing away molten material. Understanding these elements is essential to mastering the plasma cutting process and achieving superior results in your work.

Different Types of Plasma Cutting Systems

Having grasped the fundamentals of plasma cutting, it’s time to explore the various systems available to harness this technology’s potential.

Air plasma systems are your go-to for lightweight, cost-effective operations, utilizing shop air. While efficient, they might require post-cut grinding due to oxidation, affecting cutting quality.

Conventional plasma systems step up the game with up to 300 amps, efficiently slicing through thicker material thickness with a kerf of about 0.095 inches at 100 amps, ensuring faster operations.

For superior precision, high-precision plasma systems employ dual-gas and water-cooled torches, cutting at up to 400 amps and achieving a narrower kerf of 0.091 inches. This results in minimal edge preparation, making them ideal for demanding applications.

Meanwhile, mechanized plasma cutting systems offer automated plasma cutting, combining precision and repeatability in industrial settings. These systems seamlessly integrate with power sources, offering tailored solutions for diverse cutting needs.

Power Sources and Levels in Plasma Cutting

In plasma cutting, power sources are the backbone, determining the capabilities and limitations of your cutting operations. Plasma systems utilize air plasma, conventional plasma, and high-precision plasma power sources. Each serves distinct roles in thermal cutting.

Air plasma systems, using shop air, are lightweight and cost-effective, though post-cut oxidation may necessitate additional grinding. Conventional plasma systems deliver up to 300 amps, allowing rapid cutting of thicker materials, with a kerf of approximately 0.095 inches at 100 amps.

In contrast, high-precision plasma systems, operating at up to 400 amps, employ dual-gas, water-cooled torches, achieving a kerf of 0.091 inches on 1/2-inch steel, minimizing edge cleanup. Your choice of power source and output level greatly affects cutting speed, quality, and efficiency.

Higher power levels typically yield cleaner cuts and reduce edge preparation, enhancing overall cutting quality. Understanding these systems is vital for optimizing your plasma cutting operations.

The Role of Gases in Plasma Cutting

While selecting the appropriate gas for plasma cutting, it’s important to take into account how it influences cutting speed, edge quality, and the heat-affected zone.

Compressed air offers a cost-effective solution for cutting mild steel, stainless steel, and aluminum, though it may cause surface oxidation, affecting the quality. For thicker mild steel, oxygen drastically increases cutting speed but risks oxidation on aluminum and stainless steel, compromising edge quality.

Compressed air is budget-friendly for cutting metals but may lead to surface oxidation, affecting the final quality.

Utilizing nitrogen minimizes oxidation, making it ideal for achieving clean cuts on stainless steel and aluminum, especially effective on thinner workpieces. Its application in plasma cutting guarantees a precise finish and maintains material integrity.

For demanding tasks, argon/hydrogen gas mixtures provide the hottest plasma, excelling in cutting thick stainless steel and aluminum. This combination delivers smooth, high-quality cuts but necessitates heightened safety measures due to its complexity and cost.

Each gas choice directly impacts the cutting outcome and operational efficiency.

Comparing Plasma Cutting With Other Cutting Methods

When evaluating different cutting technologies, understanding the strengths and limitations of each method is essential for optimizing your manufacturing processes.

Plasma cutting machines excel in metal cutting, offering an effective solution for thicker materials, up to 1.5 inches, thanks to the robust plasma power source. They deliver superior cut quality and speed compared to oxy-fuel cutting, which is limited in accuracy and primarily used for thicker metals.

In contrast, laser cutting provides unparalleled precision for thinner materials, less than 1 inch, and can handle both conductive materials and non-metal substrates, broadening its application scope. However, laser systems are generally more costly than plasma cutters, which are advantageous for medium-thickness cutting processes.

While waterjet cutting shares laser cutting’s precision, it surpasses plasma by cutting non-conductive materials as well.

Weighing these advantages and disadvantages helps you select the proper method to enhance operational efficiency and product quality in your metalworking operations.

Enhancing Plasma Cutting Precision and Efficiency

You’ll enhance plasma cutting precision and efficiency by maintaining ideal torch distance, which is critical to achieving consistent kerf widths and reducing material waste.

Leverage advanced CNC controller technology to make real-time adjustments, allowing you to tackle intricate designs with improved edge quality.

Optimal Torch Distance

Achieving ideal torch distance is key to enhancing plasma cutting precision and efficiency. Maintaining an optimal torch distance guarantees consistent plasma arc stability, directly impacting cutting quality.

Consider these essential factors:

- Material Thickness: Adjust the torch height to match the material’s thickness for clean cuts. Different materials demand unique spacing to maintain plasma arc stability.

- Power Settings: Calibrate power settings accurately. Appropriate power levels help sustain ideal torch distance, vital for precision cutting systems.

- Height Control Technologies: Employ advanced height control technologies to automate torch adjustments, minimizing manual intervention and boosting productivity.

- Gas Flow: Regulate gas flow precisely, as it influences torch height and cutting performance.

Incorrect torch distance results in poor cut quality and increased consumable wear, affecting production efficiency.

Real-Time Adjustments

Although plasma cutting is inherently precise, real-time adjustments elevate this precision and efficiency to new heights by dynamically managing critical variables such as gas flow, torch distance, and cutting speed during operation. With intelligent CNC systems, you can make real-time adjustments that enhance cut quality and accuracy, minimizing dross and reducing edge preparation time. High-end controllers allow improvement for complex shapes, offering both “best quality cut” and “lowest cost cut” options.

| Feature | Benefit |

|---|---|

| Real-Time Adjustments | Improved cut quality |

| Intelligent CNC Systems | Enhanced accuracy |

| Advanced Software Tools | Boosted production efficiency |

| Precision Controls | ideal torch distance |

Advanced software tools also integrate seamlessly with your system, enabling features like cost calculators and CAD tools, further enhancing production efficiency.

Controller Technology Advancements

Building on the real-time adjustments empowered by intelligent CNC systems, new advancements in controller technology further refine plasma cutting precision and efficiency. High-end controllers drastically enhance cut quality by meticulously managing variables like gases, torch distance, speed, and current. This results in reduced dross and superior precision.

Key advancements include:

- Automation Integration: Seamlessly incorporate CAD/CAM software, simplifying workflows and boosting productivity.

- Precision Management: Achieve minimal edge preparation with cut accuracy from ±0.01 in. to 0.05 in., ensuring smooth surfaces.

- Operating Systems: Utilize specialized OS like Windows 7 Embedded, enhancing reliability and reducing high-frequency interference.

- Intelligent Adjustments: Harmonize components for peak performance, offering options like “best quality cut” or “lowest cost cut.”

These technologies empower plasma cutting systems with remarkable reliability and efficiency.

Frequently Asked Questions

What Type of Power Source Is Used for Plasma Cutting?

You use a plasma arc power source, considering cutting thickness, gas flow, and nozzle design. Focus on consumable parts for maintenance, guarantee operator safety, optimize for metal types and cutting speed, and prioritize power efficiency for best results.

Is Plasma Cutting AC or DC?

Plasma cutting typically uses DC for enhanced plasma arc stability, ideal cutting speed, and power efficiency across various metal thicknesses. Confirm equipment maintenance, consider gas types, and follow safety measures to maximize cost, portability, and industry applications.

Are Plasma Cutters 110 or 220?

Imagine cutting thick steel with ease; you’d choose a 220-volt plasma cutter for its power efficiency and superior cutting thickness. However, 110-volt types offer portability for lighter tasks. Consider duty cycle, cost, and safety measures.

What Power Does a Plasma Cutter Need?

You’ll need a plasma cutter that converts AC to DC power, typically between 200-400 VDC. Consider amperage settings for material thickness and cutting speed. Prioritize efficiency, portability, and safety. Regular maintenance guarantees peak performance and cost-effectiveness.

Conclusion

You’ve journeyed through the electrifying world of plasma cutting, where sparks fly and precision reigns supreme. With a solid grasp of system types, power sources, and gas choices, you’re equipped to release your cutting prowess. Picture the torch as an artist’s brush, crafting masterpieces with high precision. By mastering torch distance and CNC technology, you’ll cut through challenges like a hot knife through butter, achieving results that are nothing short of cutting-edge brilliance.