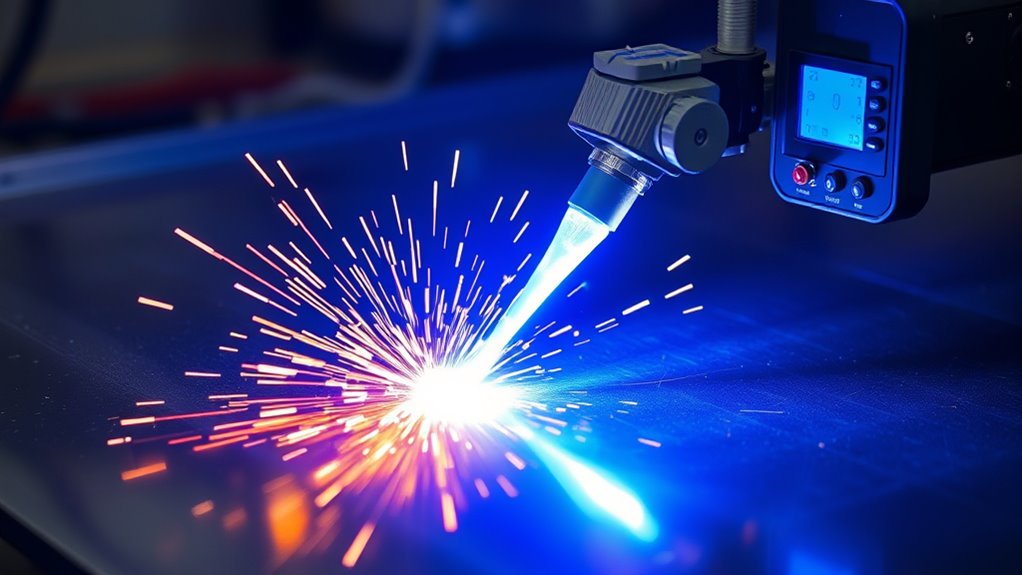

Imagine if plasma cutting could be as effortless as slicing through butter, producing pristine edges free from dross. Achieving such precision demands a methodical approach. By fine-tuning your cutting parameters, maintaining the correct torch height, and using quality consumables, you can substantially reduce dross formation. Regular maintenance and exploring automation can further enhance your results. There’s more to uncover about ensuring cleaner cuts with fewer hassles.

Understanding Dross and Slag in Plasma Cutting

Dross, a common byproduct of plasma cutting, refers to the unwanted waste that forms on or beneath cut edges due to molten metal solidifying when there’s insufficient air or gas pressure.

Dross formation occurs because plasma cutting requires precise control over factors like cutting speed and amperage. If these parameters aren’t correctly set, you’ll likely encounter more dross.

Precise cutting speed and amperage control are key to minimizing dross in plasma cutting.

Unlike dross, which is specific to plasma cutting, slag differences arise as slag generally pertains to oxy-fuel cutting processes.

Understanding these differences is essential for optimizing your cutting operations. To minimize dross, guarantee your machine’s parameters are finely tuned.

Consistent equipment maintenance and replacing worn consumables will help reduce dross accumulation. By addressing these elements, you can achieve cleaner cuts and enhance your production efficiency.

Why Dross and Slag Are Problematic

When dross accumulates on cut edges, it can cause significant production delays and bottlenecks, especially in high-volume fabrication environments.

You’ll often need to use tools like angle grinders to remove this buildup, risking surface alteration and potential discoloration of sensitive metals.

Even experienced operators encounter these issues, emphasizing the importance of correctly setting plasma cutting parameters and maintaining equipment.

Production Delays and Bottlenecks

Although efficient production is the goal, the presence of dross and slag can considerably hinder workflow in metal fabrication. These unwanted byproducts delay production times, as removing them often requires additional labor and equipment. This creates potential bottlenecks that disrupt production efficiency and hinder workflow optimization.

When hardened dross forms, you’ll need tools like angle grinders for removal, complicating the process and potentially altering material surfaces. Smaller shops, lacking automated systems, face even greater challenges, struggling to manage large batches manually.

Sensitive metals may suffer discoloration and property loss during dross removal, impacting final product quality. To counter these issues, continuously monitor and optimize your cutting parameters, reducing dross accumulation and enhancing overall cutting efficiency, minimizing production delays.

Surface Alteration Concerns

Efficient production workflows can be severely impacted by surface alteration concerns stemming from dross and slag. Dross removal isn’t just time-consuming; it also risks altering the surface finish of metals. This can lead to discoloration or a loss of critical metal properties, especially when using tools like angle grinders. Excessive dross buildup often requires mechanical removal, adding more time and labor.

| Problem | Impact |

|---|---|

| Delayed Production | Increased operational costs |

| Surface Finish Alteration | Compromised metal properties |

| Extensive Cleanup | Hindered efficiency |

In small shops, manually removing dross from large batches hinders efficiency, complicating adherence to production schedules. The compromised quality of the final product can lead to additional rework, impacting customer satisfaction and profitability. Maintaining ideal cutting conditions minimizes these issues.

Setting Optimal Plasma Cutting Parameters

To achieve ideal plasma cutting results, you must meticulously set your cutting parameters.

Begin by fine-tuning your cutting techniques through methodical parameter adjustments. Verify the cutting speed aligns with the best arc lag range of 15-30 degrees behind the torch. This minimizes dross formation and enhances edge quality. Always keep the torch height steady at 1/16-inch to 1/8-inch from the workpiece. This consistency maintains proper arc voltage, reducing bevel angle variations.

Consult your plasma cutter’s manual for specific settings tailored to the material type and thickness. Each cutter system has unique parameters for peak performance.

Regularly monitor and replace worn consumables like tips and electrodes, as these directly affect cutting quality. Utilize the Beacon app or similar tools to sustain consistent arc voltage during cutting. This precision leads to cleaner edges and reduced dross.

Adhering to these practices guarantees ideal plasma cutting results.

Maintaining Consistent Torch Height

To maintain ideal arc voltage, confirm your torch height remains between 1/16-inch and 1/8-inch from the workpiece.

Adjust the torch height according to material thickness and type, as inconsistencies can affect cut quality and bevel angles.

Use the Beacon app to get real-time feedback on your torch height adjustments, helping you counteract any disruptions caused by material inconsistencies.

Optimal Arc Voltage

Although it might seem minor, maintaining a consistent torch height is vital for achieving optimal arc voltage in plasma cutting.

Keeping the torch between 1/16-inch to 1/8-inch from the workpiece guarantees ideal torch voltage and arc stability. Deviations lead to increased voltage, affecting cut quality and causing excessive dross.

Consult your plasma cutter’s cut charts to determine the ideal arc voltage for your specific material and thickness. Regular monitoring is significant; fluctuations can disrupt cutting performance.

Utilize the Beacon app for real-time feedback on torch height and cutting conditions. This guarantees your torch voltage remains stable, preventing voltage spikes and maintaining the quality of your cuts.

Focus on consistency to achieve cleaner edges with minimal dross.

Torch Height Adjustments

Even the slightest misalignment in torch height can greatly impact plasma cutting performance.

Maintaining a consistent torch height of 1/16-inch to 1/8-inch is critical for ideal cutting quality. This precise torch height calibration minimizes dross formation and guarantees cleaner edges.

Adjust your torch height according to material thickness and type, as variations can lead to poor cuts. Inconsistencies disrupt arc voltage, causing uneven bevel angles and compromised quality.

Implement height adjustment techniques, such as using the Beacon app, to monitor and maintain stable arc voltage. Regularly check and adjust the torch height throughout your cutting process.

This methodical approach enhances edge quality, reduces post-cut cleanup, and assures precision. Consistent calibration is essential for achieving professional-grade results.

Material Inconsistencies Impact

While cutting with a plasma torch, you’ll find that maintaining a consistent torch height is vital for quality results, yet material inconsistencies pose a significant challenge.

Variations in material thickness and surface texture can disrupt the ideal torch height of 1/16-inch to 1/8-inch, causing uneven cuts and increased dross. Regularly check and adjust the torch height to accommodate these variances, ensuring best edge quality.

Cutting speed and operator experience also impact the outcome. Proper equipment calibration is essential, as inconsistent torch height can lead to varying bevel angles.

Utilizing the Beacon app can assist in maintaining consistent arc voltage, directly influenced by torch height and material properties, thereby minimizing complications and achieving cleaner cuts with reduced dross.

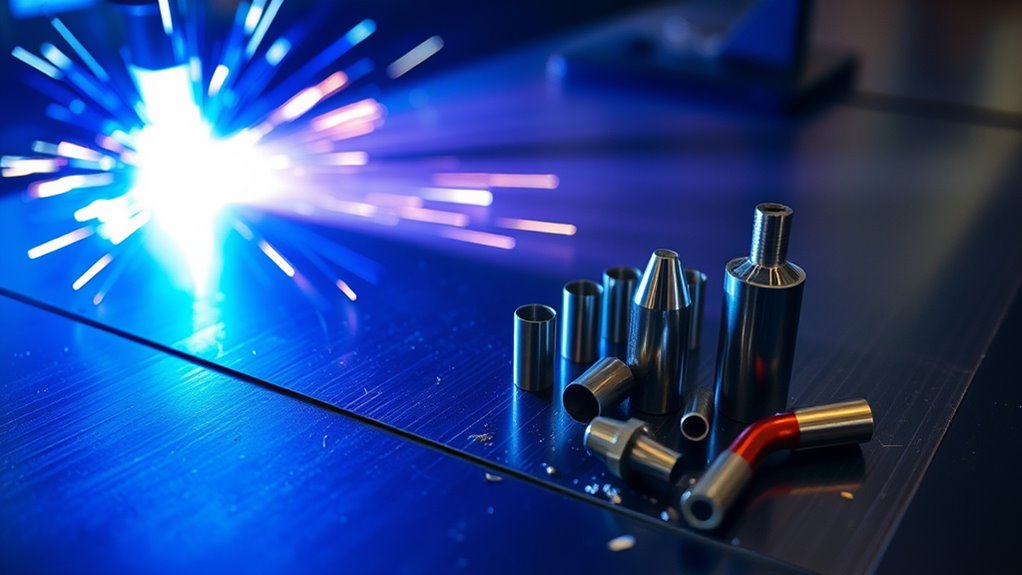

Selecting the Right Consumables

Why is selecting the right consumables so essential for effective plasma cutting? It’s because the consumable materials, including electrodes and nozzle types, directly impact the quality of your cuts and the amount of dross produced.

Using the correct nozzle type, such as a fine-cut nozzle for thin materials, can improve edge quality and minimize dross accumulation. High-quality consumables prevent increased dross formation caused by worn or damaged parts.

Opt for fine-cut nozzles to enhance edge quality and reduce dross on thin materials.

Regularly inspecting and replacing consumables, ideally every 1-2 hours of cutting, maintains peak performance. Verify that consumables are compatible with your specific plasma cutter model to enhance cutting efficiency and achieve cleaner edges.

Additionally, investing in advanced consumable technologies like single-piece cartridges can simplify replacements, verifying consistent quality and reducing dross production.

Techniques for Dross and Slag Removal

Effectively removing dross and slag is essential for maintaining the quality of your plasma-cut edges. Start by using mechanical grinders with rotating pins; they excel at dross removal, speeding up the cleanup compared to manual techniques.

For medium-thickness dross, equip angle grinders with flap discs. These provide efficient slag management without excessive effort. Lighter dross accumulations benefit from wire brush wheels, which gently clean surfaces.

To prevent dross from sticking, apply anti-spatter sprays. This step reduces subsequent cleanup, enhancing cutting efficiency.

In cases of stubborn dross, use sanding systems like Norton Abrasives AVOS disks. They swiftly eliminate dross while preserving the integrity of the underlying metal.

Implementing these precise techniques guarantees cleaner edges, ultimately improving the quality of your work. By methodically selecting the right tools and preventive measures, you’ll achieve ideal results in dross removal and slag management.

Regular Maintenance and Equipment Care

Proper dross removal is just one aspect of guaranteeing high-quality plasma cuts; maintaining your equipment is equally crucial. Implementing preventive maintenance will enhance equipment longevity and performance.

Begin by regularly inspecting consumables—nozzles, electrodes, and swirl rings. Replace any worn parts to maintain cutting precision and minimize dross. Don’t neglect the power source; keep it free from metal dust and contaminants to promote efficient electrical flow and stable arc conditions.

Inspect consumables regularly and replace worn parts to ensure cutting precision and reduce dross formation.

Schedule routine checks of the plasma cutter. Examine connections and clean the torch to prevent issues that could increase dross accumulation. Secure the work clamp to a clean surface for ideal electrical connectivity, essential for consistent cut quality.

Establish a regular cleaning schedule for the cutting area and tools. This practice minimizes dross adherence and enhances workflow efficiency, assuring your equipment remains reliable and effective over time.

Prioritize maintenance, and your plasma cutter will serve you well.

Exploring Automation and Advanced Technologies

Although manual plasma cutting has its merits, embracing automation and advanced technologies can revolutionize your cutting processes. Implementing automated systems like the Cobot Cutter allows cutting speeds to exceed 100 inches per minute, greatly boosting productivity.

You’ll find automation benefits extend beyond speed; Hypertherm’s SmartSYNC technology guarantees consumable wear is minimized and performance remains steady, thanks to seamless technology integration.

Consider these advancements to enhance your operations:

- Collaborative Robots (Cobots): Utilize flexible programming to quickly adapt to changing production needs, reducing the need for extensive operator training.

- Single-Piece Cartridges: Streamline consumable replacement, reducing downtime and preserving cut quality.

- Cutting Time Reduction: Automation can reduce cutting time by 94%, nearly eliminating rework, which results in substantial cost savings and increased throughput.

Frequently Asked Questions

How Does Material Thickness Affect Plasma Cutting Quality?

Material thickness directly affects cutting quality. Thicker materials require slower cutting speeds for precision. Ideal material selection guarantees cleaner cuts. Adjust settings accordingly to maintain efficiency and minimize dross, keeping the process controlled and results consistent.

What Role Does Gas Type Play in Plasma Cutting?

Gas selection is the conductor in your plasma cutting symphony, directing cutting efficiency. Choose the right gas to enhance arc stability, minimize dross, and achieve cleaner edges, ensuring precision and quality in your metalwork projects.

Can Plasma Cutting Be Used on All Metals?

You can’t use plasma cutting on all metals. Plasma cutting metals depends on metal compatibility; it’s ideal for conductive metals like steel, stainless steel, and aluminum. Non-conductive metals, like some alloys, aren’t suitable for plasma cutting.

How Do Environmental Factors Impact Plasma Cutting Performance?

Environmental factors like temperature control and humidity levels directly impact plasma cutting performance. You should maintain stable temperatures and low humidity to guarantee ideal arc stability and precision, minimizing dross and achieving cleaner edges on your workpiece.

What Safety Precautions Are Necessary During Plasma Cutting?

Make certain you wear personal protective equipment like gloves, goggles, and flame-resistant clothing. Regularly inspect and maintain equipment to prevent malfunctions. Keep the work area ventilated and free of flammable materials to minimize risks during plasma cutting.

Conclusion

To achieve cleaner edges and reduce dross in plasma cutting, you need to fine-tune your parameters, maintain a consistent torch height, and select the right consumables. Inspect your equipment regularly, replace worn parts promptly, and apply anti-spatter sprays effectively. Embrace automation for enhanced precision, increased productivity, and minimized cleanup. By aligning your cutting speed with the ideal arc lag and integrating advanced technologies, you’ll optimize performance, improve efficiency, and elevate your cutting results.