When using a plasma cutter with a generator, you must focus on clean power, wattage, and Total Harmonic Distortion (THD). Ensuring your generator supplies the right wattage, ideally 20-21kVA, is critical for meeting the amperage demands. THD should be below 5% to maintain the cutter’s performance and longevity. Clean power prevents inconsistent cuts and potential damage. What’s the next step in ensuring your setup is ideal?

Understanding Plasma Cutter Power Requirements

When you’re considering using a plasma cutter with a generator, understanding the power requirements is essential. Plasma cutters typically demand substantial power, with some models reaching power ratings up to 1,000 amps at full capacity. However, they seldom operate at full power continuously.

It’s critical to match the plasma cutter’s power rating with the generator’s output to guarantee compatibility. Generators must handle the startup currents, which can surge considerably, stressing the cutter’s components. Assess the generator’s capacity to manage these startup demands effectively.

Older generators might offer superior voltage regulation, aiding in maintaining consistent power delivery. Evaluate the generator’s voltage stability and its ability to handle surge currents without causing mechanical stress.

Additionally, verify that circuit breakers are upgraded to accommodate the high power requirements, as standard breakers often cap at 15 or 20 amps. This guarantees seamless operation, safeguarding both the plasma cutter and the generator.

The Importance of Clean Power for Plasma Cutters

Even though you might overlook it, clean power is essential for plasma cutters to function at their best. Voltage stability is important; fluctuations can cause inconsistent cutting, inefficient operation, and equipment damage.

When using a generator, make sure it provides clean energy with minimal Total Harmonic Distortion (THD). High THD levels lead to reduced efficiency and accelerated wear on your plasma cutter’s components.

A generator’s well-regulated output is significant, especially during startup surges. Check its specifications for voltage regulation and THD levels. This guarantees compatibility with your plasma cutter’s power demands, maintaining performance and reliability.

Clean energy enhances cutting precision and extends the plasma cutter’s lifespan, making it a key factor when operating on generator power.

Evaluating Generator Wattage for Plasma Cutting

When evaluating generator wattage for plasma cutting, assess the generator’s kW rating to guarantee it meets the plasma cutter’s amperage demands, like those of the Stahlwerk cut70.

Confirm the generator’s ability to handle surge currents and harmonic distortions to prevent stress and maintain operational integrity.

It’s essential to match the generator’s power output and compatibility specifications with the plasma cutter’s requirements for peak performance and safety.

Generator Compatibility Factors

To guarantee peak performance from your plasma cutter, it’s essential that your generator’s wattage meets or surpasses the cutter’s power requirements—typically around 60-70 amps.

Different generator types, like older models, might offer unexpected voltage regulation benefits, but their load capacity can be limited by an output of approximately 28A per phase. This constraint necessitates a suitable transformer type to bridge compatibility gaps with higher amperage cutters.

Be vigilant about surge current during start-up, as it can strain the generator and equipment, emphasizing the need to evaluate dynamic load handling.

Additionally, monitor total harmonic distortion (THD); excessive THD can undermine your plasma cutter’s performance and longevity.

Ascertain your generator maintains a clean, stable power output for peak cutting efficiency.

Power Output Considerations

Understanding the synergy between your generator’s wattage and your plasma cutter’s demands is fundamental for achieving peak performance.

Begin by scrutinizing the power ratings of your generator. A unit rated at 17kW (about 20-21kVA) delivering 28A per phase is a critical parameter for compatibility with the cutter’s power requirements.

Plasma cutters require substantial power, often needing up to 1,000 amps at full output. Consequently, consider the generator types you’re evaluating; verify they can manage the initial surge current when the cutter starts.

Significantly, older generators might offer robust voltage regulation, but verify their capacity. Additionally, monitor Total Harmonic Distortion (THD) levels, as excessive THD can impair the cutter’s functionality.

Upgrading circuit breakers or installing dedicated outlets may be necessary.

Total Harmonic Distortion: Impact on Plasma Cutter Performance

When using a plasma cutter with a generator, it’s essential to monitor Total Harmonic Distortion (THD) as it directly affects cutting efficiency and component longevity.

High THD levels can destabilize the arc, resulting in poor cutting precision and increased wear on the cutter.

Ascertain the generator maintains THD below 5% to optimize performance and prevent potential damage.

Harmonic Distortion Effects

Although often overlooked, total harmonic distortion (THD) plays an important role in the performance of plasma cutters, especially when operated on generator power.

Conducting a harmonic analysis is vital for identifying excessive distortion levels, which can lead to overheating and premature failure of electronic components. Without adequate distortion mitigation, plasma cutters struggle to maintain stable arc quality, resulting in inefficiencies and erratic operations.

To address these issues, make certain your generator features advanced voltage regulation and three-phase sensing. These technologies help reduce THD, aligning the power supply with the sensitive requirements of plasma cutters.

Monitoring THD levels is important, particularly with older generators, to assure best performance and extend equipment longevity. Prioritize a clean power source to avoid disruptions in your cutting tasks.

Plasma Cutter Efficiency

Plasma cutter efficiency hinges on maintaining low Total Harmonic Distortion (THD) levels, essential for precise and stable cutting operations. High THD disrupts arc stability, undermining plasma cutting techniques and resulting in subpar cuts.

To achieve efficiency enhancements, guarantee your generator provides clean power. Excessive THD from older generators can compromise precision, stressing the cutter’s electronics.

Key steps to optimize plasma cutter efficiency:

- Monitor THD levels: Regular checks prevent inconsistencies.

- Use modern generators: They typically produce lower THD.

- Adhere to voltage specifications: Align generator output with cutter requirements.

- Incorporate power conditioners: They help reduce THD impact.

- Perform regular maintenance: Keeps equipment in peak condition.

Selecting the Right Generator for Your Plasma Cutter

Choosing the right generator for your plasma cutter is critical to guaranteeing efficient operation. Start by evaluating generator types and power ratings. A generator with a power output of around 20-21kVA is preferable, as it supports the plasma cutter’s starting and running current demands effectively.

Confirm the generator is equipped with automatic voltage regulation (AVR) to stabilize voltage during operation and accommodate surge demands. Pay attention to the total harmonic distortion (THD); aim for a generator with low THD to protect sensitive electronic components in your plasma cutter.

Opt for a generator with a three-phase output if your plasma cutter model benefits from such enhanced compatibility and performance. Verify that the generator’s rated current output is approximately 28A per phase, confirming it meets your plasma cutter’s operational requirements.

Precision in these specifications is crucial for maximum plasma cutting performance and equipment longevity.

Managing Power Fluctuations and Voltage Regulation

When managing power fluctuations and guaranteeing voltage regulation for your plasma cutter, precision matters. Voltage stability is vital, particularly with older generators prone to overvoltage when current demand drops. This can detrimentally affect your plasma cutter’s performance.

By adjusting generator settings, you can regulate voltage, whether manually or automatically, to maintain peak operation. It’s important to align the generator’s output with the plasma cutter’s needs, especially during start-up, when surge current can strain generator components.

Consider these key points:

- Monitor voltage stability: Regularly check for overvoltage or undervoltage issues.

- Adjust generator settings: Utilize the voltage adjustment knob for precise control.

- Evaluate surge current: Verify the generator can handle peak demands.

- Mitigate harmonic distortion: Keep THD levels low to protect performance.

- Match generator and cutter specs: Verify compatibility to avoid operational issues.

Adhering to these guidelines guarantees seamless plasma cutting operations.

Ensuring Compatibility Between Generator and Plasma Cutter

Before you begin using a plasma cutter with a generator, verifying compatibility between the two is essential for ideal performance and longevity. Start by confirming the plasma cutter model’s amperage requirements align with your generator’s output, ideally around 60-70 amps. Attention to the generator type is vital; older models, like a 17kW unit, may excel in voltage regulation but can lead to overvoltage when demand drops. Evaluate the generator’s surge capability to manage the initial load when the plasma cutter starts, preventing undue stress on both devices. Inverter-type plasma cutters demand more consistent power, so check manufacturer specifications to verify compatibility. Employing a generator with an Automatic Voltage Regulator (AVR) can provide the stable output needed.

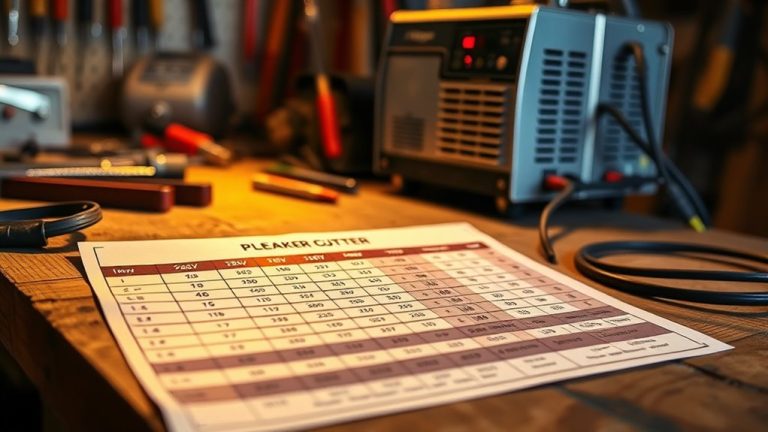

| Generator Type | Plasma Cutter Model | Key Consideration |

|---|---|---|

| 17kW Old Model | Transformer | Voltage regulation, overvoltage |

| Inverter | Inverter | Consistent power supply |

| AVR Equipped | Any | Stable power output |

Troubleshooting Common Power Issues With Plasma Cutters

Many encounter issues with plasma cutter performance when powered by generators, often due to unstable power supply.

A critical aspect is understanding how surge currents can create stress on your cutter. When the generator can’t handle these sudden demands, it can lead to power fluctuations that potentially damage your equipment.

To troubleshoot common power issues, consider these steps:

- Assess Generator Capacity: Confirm your generator can provide a stable power supply with minimal total harmonic distortion (THD).

- Monitor Surge Currents: Evaluate your generator’s ability to handle the initial high current surge typical of plasma cutter start-ups.

- Upgrade Circuit Breakers: Standard 15-20 amp breakers may not suffice; consider higher-rated options.

- Install Dedicated Outlets: These outlets can better manage the cutter’s power demand.

- Consult a Professional: An electrician can evaluate if your generator meets the high power requirements of plasma cutting, preventing overvoltage issues.

Precision in troubleshooting confirms efficient and safe operation.

Expert Tips for Optimal Plasma Cutter Performance on Generators

Understanding the electrical demands of plasma cutters is key to preventing power issues when using a generator. First, verify your power source can handle surge currents during startup, avoiding stress and potential component failure. A plasma cutter rated between 60-70 amps ideally matches a generator output of ~28A per phase.

To further enhance performance, monitor total harmonic distortion (THD); older generators often produce higher THD, which can impair your plasma cutter’s function and longevity.

For consistent results, consider a transformer-type plasma cutter, as they better accommodate fluctuating generator power outputs compared to inverter models, which demand more precise voltage and current regulation.

Finally, consult the plasma cutter’s manufacturer specifications to verify compatibility with your generator’s voltage and current capabilities. This alignment is essential for maintaining efficient cutting techniques and guaranteeing seamless operation.

Frequently Asked Questions

Can I Use Solar Power to Run a Plasma Cutter?

Yes, you can use solar power to run a plasma cutter. Make sure your solar setup provides sufficient wattage and current. Consider plasma efficiency and make certain your inverter delivers clean, stable output for seamless operation. Evaluate Total Harmonic Distortion (THD).

How Do Weather Conditions Affect Plasma Cutter Performance?

Don’t worry about minor weather fluctuations; focus on extremes. High temperatures can cause overheating, while high humidity impacts arc stability. Maintaining ideal conditions enhances precision. Monitor temperature effects and humidity impact to guarantee consistent plasma cutter performance.

What Are the Best Safety Practices When Using a Plasma Cutter?

Make certain you wear appropriate PPE, including gloves, eye protection, and flame-resistant clothing. Maintain a safe workspace; keep flammable materials away, make certain proper ventilation, and secure grounding. Regularly inspect equipment for defects to prevent hazards.

How Often Should I Maintain My Generator for Plasma Cutting?

For maximum plasma cutter efficiency, you should maintain your generator every 50-100 hours. Isn’t it wise to guarantee longevity by checking filters, spark plugs, and oil levels? Regular maintenance prevents downtime and boosts your generator’s performance.

Are There Portable Options for Plasma Cutters and Generators?

You’ll find various portable plasma cutter options that guarantee generator compatibility. Consider models with inverter technology for efficient power use. Check wattage and THD levels to guarantee seamless operation and ideal performance while on-site.

Conclusion

When using a plasma cutter with a generator, ensuring clean power, precise wattage, and minimal THD is not just important—it’s absolutely essential for performance sharper than a razor’s edge. Choose a generator with around 20-21kVA and THD under 5% to keep your cuts consistent and your equipment unharmed. By managing voltage fluctuations and ensuring compatibility, you’ll wield your plasma cutter with the precision of a master craftsman, turning every project into a masterpiece of technical excellence.