In this guide I lay out 12 practical, easy-to-follow welding tips for beginners that I teach in my video “12 Welding Tips for Beginners | Basic Welding Guide | Arc Welding Tips and Tricks.” Whether you are just starting with arc welding, want to improve bead consistency, or need clear rules for joint preparation and electrode handling, this article compiles the core fundamentals I demonstrate on the bench and expands them with practical explanations, examples, and drills you can use right away.

This post follows a listicle format — 12 numbered, focused tips — each broken down with clear instruction, what to watch out for, and short practice exercises. You’ll also find images taken at key moments in the video to help visualize what I’m teaching (timestamps included). I keep the same direct, practical tone I use in the workshop: plain, useful, and no-nonsense. Let’s jump in.

1. Choose the Right Electrode and Know Its Numbering ⚙️

Choosing the correct electrode for your job is one of the most impactful decisions you’ll make as a beginner. Electrode selection determines penetration, bead profile, and how easy it is to maintain a stable arc. For shielded metal arc welding (SMAW or stick welding), the electrode number gives an at-a-glance summary of its properties:

- The first two digits indicate minimum tensile strength in ksi (e.g., “60” = 60,000 psi).

- The third digit indicates welding positions (“1” for all positions, “2” for flat and horizontal only).

- The last two digits indicate the flux coating and suitable current/polarity (AC/DC) and operating characteristics.

Reference: AWS SMAW classification as summarized by Lincoln Electric (AWS Classifications).

For beginners working on general purpose mild steel, I often recommend E6011, E6013, or E7018 depending on the material thickness and position:

- E6013 — forgiving, smooth arc, good for thin material and beginners; typically runs well on AC and DC. See Lincoln’s Fleetweld 37 (E6013) description and datasheets for use on small AC welders and sheet metal.

- E6011 — digs into rust/paint better with a deep, penetrating arc; good for root passes and for welding over moderate contaminants; usable on AC or DC per product recommendations.

- E7018 — low-hydrogen rod for higher quality structural work where cracking resistance matters; commonly run on DCEP (reverse polarity) or AC on AC-rated variants (e.g., Lincoln 7018 AC). Keep low-hydrogen rods dry — after opening, store around 250–300°F (120–150°C) per manufacturer guidance and redry as specified.

Tip: always follow the material and code requirements when selecting electrodes for critical work. For practice, buy a small pack of E6013 to master the arc and bead appearance before moving on to low-hydrogen rods like E7018.

Practice drill

Take three short rods—E6013, E6011, E7018. Weld three identical beads on scrap 3 mm (1/8″) steel with each rod at recommended amperage. Compare bead appearance, penetration, and ease of striking the arc. Note which rod gives you the results you prefer and why.

“1 kg of chicken breast”

Yes, I sometimes use odd phrases when I’m concentrating or while recording practice. It’s a tiny moment of humor that helps me explain rhythm—just like repeating a phrase while setting your travel rhythm when welding a bead.

2. Match Amperage to Electrode and Material Thickness 🔥

Amperage controls penetration, bead profile, and the heat input to the job. Too low and the bead will be cold and sit on top of the metal with poor fusion; too high and you’ll burn through thin stock or create excessive slag and undercut. Each electrode has a recommended amperage range printed on the packaging — use that as your starting point.

General amperage guidelines for stick welding on mild steel (approximate):

- 1/16″ (1.5 mm) — ~40–90 A

- 1/8″ (3.2 mm) — ~75–150 A

- 3/16″ (4.8 mm) — ~125–200 A

- 1/4″ (6.4 mm) — ~175–250 A

When you set amperage, pay attention to arc behavior:

- Short, sputtery arc = too low amperage or too long arc length.

- Excessive spatter, deep undercut = too high amperage or too fast travel speed.

- Smooth slag release and a steady bead = correct amperage and arc length.

Practice drill

On a single electrode type and a scrap plate, weld a series of short beads increasing amperage by 10 A each time. Observe and note how the bead shape and penetration change. This is one of the fastest ways to feel the effect of amperage changes.

3. Keep the Correct Arc Length and Maintain a Steady Travel Speed ✨

Arc length affects bead width and penetration. A short arc (electrode close to work) gives more penetration and a narrower bead, while a long arc yields a wider, flatter bead with more spatter and poorer fusion. For most stick electrodes, maintain an arc length about equal to the diameter of the electrode (a 3.2 mm rod ≈ 3.2 mm arc length).

Travel speed also interacts with arc length and amperage. Go too fast and you’ll have thin, poorly fused beads that may lack reinforcement. Go too slow and you risk burn-through, excessive reinforcement, and strong convex beads.

- For a neat flat bead: moderate amperage, short arc length, steady travel speed—move at a pace that forms a consistent puddle and leaves the bead with uniform width.

- For thin materials: reduce amperage, shorten arc length, and keep travel speed slightly faster to avoid burn-through. For more, see my walkthrough on stick welding thin sheet metal.

- For thicker materials: higher amperage and slightly slower travel speed to achieve full penetration.

Practice drill

Set up a scrap plate, choose a rod and recommended amperage. Make three beads: one with intentionally long arc, one with correct arc length, and one with very short arc. Compare the results and use a grinder to inspect penetration if possible.

4. Angle Matters: Work Angle vs. Travel Angle 🧭

The angle at which you hold the electrode is often misunderstood. There are two common angles to watch:

- Work angle — the angle relative to the workpiece across the joint (helps control bead placement).

- Travel angle — the angling of the electrode in the direction of travel (helps control penetration and puddle).

For a typical butt or lap joint working in the flat position, a travel angle of 5–15 degrees into the weld (push or drag depends on process and electrode) is common. When forming fillet welds, the electrode is often held closer to perpendicular to the joint but with a slight push or drag to direct the molten metal into the joint.

Here’s a simple rule of thumb:

- For most stick welding, drag the electrode slightly (5–15°) to help the puddle cover the joint and promote fusion.

- For thin metal or rapid travel, you may push slightly to reduce penetration and flatten the bead.

Practice drill

Mark lines on a scrap plate and weld beads at 0°, 10°, 20°, and 30° travel angles. Observe bead shape, penetration, and spatter. This helps you build muscle memory for the feel of correct angles.

5. Joint Fit-Up and Groove Preparation — The Foundation 🧱

Good welding starts with good fit-up. Gaps, poor alignment, and dirty edges make welding harder and less predictable. Always spend time preparing joint edges and fit-up before striking an arc. Clean, square edges and consistent root gaps lead to predictable penetration and less rework.

- Butt joints on thin materials often require no bevel; for thicker materials bevel appropriately (single V, double V, J, or U groove) to enable full penetration with manageable heat input.

- Use clamps and tacks to hold alignment. Magnetic squares and parallel blocks can save time and improve precision.

- Tack welds should be spaced to hold parts together but minimized to avoid warpage. Tack welds should be ground down before final passes when necessary for fit or inspection.

When in doubt, bevel. For anything over 6–8 mm (1/4″ to 5/16″), a bevel often helps ensure your weld reaches the root and achieves the desired strength without excess reinforcement.

“Femte”

That’s a small Swedish word you might hear — it means “fifth.” I sometimes count passes or steps out loud while prepping joints or demonstrating bead sequences; little verbal anchors are handy when teaching a sequence of tasks.

Practice drill

Create a simple V-groove in two scrap plates and practice tacking, then run a sequence of root, filler, and cap passes. This teaches heat control and bead stacking.

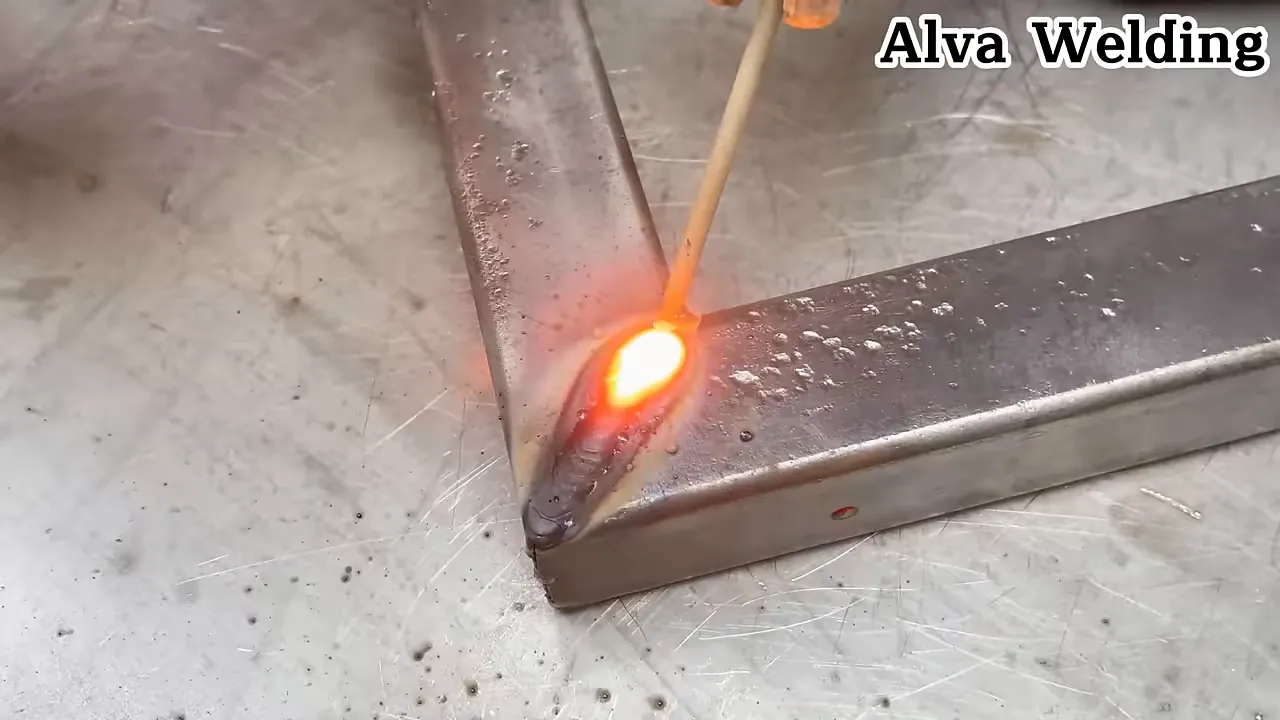

6. Strike the Arc Smoothly and Learn Puddle Control ⚡

Arc striking is a basic skill you’ll repeat thousands of times. A clean, controlled strike sets you up for a good weld. There are a few common methods to strike an arc with a stick electrode: the tap strike and scratch strike.

- Tap strike — similar to striking a match: quickly tap the electrode to the work then lift slightly to form the arc. Good for beginners and in clean conditions.

- Scratch strike — drag the electrode across the work like striking a matchstick to spark the arc. Useful when you need to start the arc in the middle of a plate or on a coated surface.

Once the arc is established, focus on the puddle — the molten pool of metal. Puddle control is the bridge between arc and bead. Learn to gauge its size and shape and adjust travel speed, angle, and amperage to maintain the desired puddle size. For general work:

- Keep a consistent puddle size for uniform bead width.

- Move slightly faster to reduce puddle size, slower to increase it.

- Watch the slag formation for each rod type to determine when to move or when to pause slightly to allow slag to form properly.

Practice drill

On a scrap plate, practice 20 short beads focusing only on strikes and stopping once the puddle is formed. Don’t worry about neatness—focus on consistent arc-strike behavior and observing how the puddle responds to small adjustments.

7. Cleanliness: Remove Rust, Paint, and Oil Before Welding 🧼

Surface contamination is a silent problem. Rust, paint, oil, and mill scale can cause porosity, weak fusion, and unstable arcs. Spend time cleaning the weld area with a grinder, wire brush, or chemical cleaner depending on the contamination:

- Wire brush for light rust and mill scale.

- Grinder for heavy scale or to shape bevels and chamfers.

- Solvent wipe for oil and grease (acetone or other degreasers).

Note that some electrodes (like E6011) tolerate less-than-perfect surfaces better because of their digging power, but for structural, pressure, or visible work always start clean.

Practice drill

Take a piece of rusty metal and divide it into zones: no cleaning, wire-brushed, and fully ground. Weld across each zone with the same electrode and amperage, then inspect bead quality and look for porosity or poor fusion.

8. Slag Control and Bead Finishing 🛠️

Many stick electrodes produce flux slag over the bead that must be removed between passes. Slag removal is not just cosmetic; trapped slag causes inclusions and weakens the weld. Use a chipping hammer and wire brush to remove slag, and always inspect the bead before adding subsequent passes.

- Hold the chipping hammer at a shallow angle and strike the slag, not the metal, to avoid pitting the bead.

- Wire brush in the direction of the bead to clear out remaining particles.

- A grinder can be used to blend the bead for appearance or to prepare for additional welding, but avoid removing too much base metal.

Practice drill

Lay a series of short beads on plate, chip and brush between each one, and then grind a small section to see how slag removal affects subsequent bead fusion. This helps you time passes and slag cleaning properly.

9. Manage Heat Input to Minimize Warpage and Distortion ♨️

Heat is your friend — and your enemy. Proper heat input ensures fusion and penetration, but excessive heat causes warpage, distortion, and weakened heat-affected zones. Control heat input through a combination of techniques:

- Shorter weld segments with intermittent cooling (stitch welding) on thin or long parts.

- Alternate welds on opposite sides of a joint to balance heat (back-step or back-and-forth sequencing).

- Use clamps and fixtures to restrain parts and prevent movement while you weld and cool.

- Limit amperage to only what’s necessary for penetration; avoid overdoing it just to speed up the job.

Also, consider preheating for thick materials or consumables that require it (e.g., some codes specify preheat for carbon steel joints above certain thicknesses) to avoid cracking and to reduce thermal gradients.

Practice drill

On two identical flat plates, weld one with continuous beads along the length and another with stitch welds spaced evenly. Compare flatness and distortion to see the practical effect of heat control.

10. Positioning and Ergonomics — Set Yourself Up to Succeed 🪑

Good posture and work positioning are underrated. If your body is uncomfortable, your hands will be unstable, and your welds will suffer. Plan your setup to minimize awkward positions and maximize control:

- Use a welding table or bench at a comfortable height. Kneeling or bending for long periods will fatigue you quickly.

- Rotate the part or re-clamp to put the joint in a more favorable welding position when possible.

- Use supports or fixtures to stabilize small parts; a jig can improve repeatability and quality. See also my beginner home welding setup.

For beginners, practice flat and horizontal welding first. Vertical and overhead require additional control and are better learned after mastering puddle control and travel speed.

Practice drill

Weld identical beads in flat, horizontal, vertical, and overhead positions. Take notes on comfort, technique differences, and bead appearance. This exercise shows how position affects technique and how to adapt.

11. Safety First: PPE and Ventilation 🛡️

Welding exposes you to bright light, hot metal, fumes, and sparks. Protect yourself and others with the right personal protective equipment (PPE):

- Auto-darkening or fixed-shade welding helmet rated for arc welding. Always use the appropriate shade for the amperage and process.

- Flame-resistant clothing or a welding jacket. Avoid synthetic materials that melt.

- Leather gloves sized to allow dexterity but protect the hands.

- Welding boots or closed-toe leather footwear.

- Hearing protection when grinding and when in noisy shops.

- Proper ventilation or local exhaust systems to remove welding fumes; use a respirator if ventilation is inadequate, especially when welding coated metals. Review OSHA Fact Sheet FS-3647 (OSHA, 2013) and NIOSH guidance on zinc oxide/welding fumes (NIOSH Pocket Guide, accessed 2025-10-16). For a gear checklist, see what protective clothing I use.

Also have a fire extinguisher nearby and clear the area of flammable materials. Plan for sparks and hot slag — they travel farther than you expect.

Practice drill

Before starting a session, do a PPE checklist and walk the workspace to identify airborne risk and combustible materials. This simple habit prevents many accidents.

“I’m going to make a little bit of”

Small practice sessions are powerful. I often say “I’m going to make a little bit of” when I mean a controlled practice bead sequence; short, focused repetition beats one long unfocused session when you’re learning.

12. Develop Muscle Memory: Repetition, Patterns, and Record-Keeping 🧠

The most reliable way to improve is deliberate practice. Muscle memory is built with repetition on consistent setups. Here’s a framework I recommend:

- Pick a single electrode, material, and amperage and practice consistent beads for a set time (e.g., 30 minutes).

- Introduce focused drills: circles, weave beads, overlapping beads, and vertical-up sequences.

- Keep a practice log: electrode, amperage, plate thickness, travel speed, and notes on what went well or what failed. Over weeks you’ll recognize patterns and progress.

- Record short videos of your hands/torch to analyze travel speed and angles — even a phone camera helps identify inconsistent movement.

When you practice intentionally, not just repeatedly, you accelerate learning. Set clear goals for each session: “30 good 6 in (15 cm) beads with uniform width,” or “nail the vertical-up sequence without slag inclusion.”

Practice drill

Create a 30-minute plan: 10 minutes of straight beads, 10 minutes of vertical-up beads, and 10 minutes of tacking and joint prep practice. Log your results and aim to improve one metric each week.

Frequently Asked Questions ❓

How do I choose between stick welding and MIG/TIG as a beginner?

Stick welding (SMAW) is robust and forgiving on dirty or rusty surfaces and requires minimal equipment—good for outdoor work and repairs. MIG (GMAW) is faster, cleaner, and easier to learn on thin sheet metal but needs shielding gas and good surface prep. TIG provides the highest quality and control, especially for thin materials and non-ferrous metals, but it has the steepest learning curve. For beginners choosing a single process: if you want portability and versatility, start with stick or MIG; if you prioritize precision and plan to work with stainless or aluminum and are ready to invest time, learn TIG. For a deeper comparison, see my MIG vs TIG guide.

What thickness can I weld with stick electrodes like E6013?

E6013 can weld thinner materials more easily than some other stick electrodes because of its softer arc, but for very thin sheet metal (less than 1.5–2 mm or 18–20 gauge), MIG or TIG are usually better because stick tends to cause burn-through. Around 1.5–6 mm (1/16″–1/4″) you can manage with an appropriate electrode diameter and reduced amperage.

Why is my weld porous and how can I stop it?

Porosity is usually caused by contamination (oil, rust, paint), moisture in the electrode coating, trapped slag, or poor shielding in processes that use gas. To fix porosity: clean the base metal, use dry electrodes (store in rod ovens for low-hydrogen rods), maintain correct travel speed and angle to allow slag to escape, and ensure gas coverage if using MIG/TIG.

How do I prevent burn-through on thin metal?

Use lower amperage, a narrower bead, shorter arc length, and faster travel speed. Consider stitch welding rather than continuous passes and opt for smaller diameter electrodes or switch to MIG/TIG for better heat control. Backing bars or chill bars (copper or steel clamps) can also help distribute and dissipate heat during welding.

What’s the difference between push and drag techniques?

Push means angling the electrode away in the direction of travel; it tends to produce flatter, wider beads with less penetration and is commonly used in MIG. Drag means angling the electrode against the direction of travel; it typically increases penetration and produces a narrower bead and is common in stick welding. Use whichever makes the puddle and bead that match your joint requirements.

How often should I replace grinding discs and wire brush heads?

Replace grinding discs when wear reduces their diameter significantly or when they become chipped or uneven—dull discs slow work and increase heat input. Wire brush heads should be replaced when bristles are worn down, bent excessively, or fall out. Regular replacement preserves efficiency and safety.

Can I weld galvanized steel?

You can weld galvanized steel, but the zinc coating produces toxic fumes and can cause porosity and weak welds. Remove the zinc from the weld area by grinding or chemical removal before welding; if not fully removable, use proper fume extraction and PPE, and be prepared to address potential porosity and adhesion issues. Zinc oxide fumes are associated with metal fume fever (OSHA FS-3647, 2013; NIOSH, accessed 2025-10-16).

What should I keep in a beginner welding toolkit?

A basic kit: welding machine, electrodes (a few types), welding helmet, leather gloves, welding jacket or apron, wire brush, chipping hammer, angle grinder with cutoff and grinding wheels, clamps, magnets, measuring tape, center punch, and a small set of chisels and hammers. Add a rod oven if you plan to use low-hydrogen electrodes regularly.

Final Thoughts and Next Steps 🚀

Welding is a hands-on skill that rewards patience, repetition, and thoughtful reflection. These 12 tips are meant to give you a solid foundation for safe, consistent, and improving arc welding practice. Remember to:

- Start with the right electrode and amperage.

- Maintain correct arc length, travel speed, and angles.

- Prepare joints carefully and control heat to avoid distortion.

- Practice deliberately and keep notes on your sessions.

- Never compromise on safety — PPE and ventilation are non-negotiable.

One more quick reminder I often say while teaching: keep your sessions short and focused. “I’m going to make a little bit of” practice each day rather than attempting marathon sessions where form degrades. Over time those small, consistent sessions build the control you need to tackle bigger projects.

Thanks for reading. If you want to follow along visually, check out the full tutorial from my workshop where I demonstrate all these tips in action. Keep your tools ready, your headlamp charged (if you work at odd hours), and your curiosity open. Welding is a craft — get comfortable with being a learner, and the progress will follow.

References

- Lincoln Electric — AWS Classifications overview (SMAW numbering).

- Lincoln Electric — Lincoln® 7018 AC (E7018 H8) product page.

- Lincoln Electric — Storing & Redrying Electrodes (PDF).

- Miller — Stick Welding Settings Calculator.

- Miller — Good Weld / Bad Weld poster (travel speed effects).

- OSHA FS-3647 — Controlling Hazardous Fume and Gases during Welding (PDF).

- NIOSH Pocket Guide — Zinc oxide (metal fume fever).

- Lincoln Electric — Fleetweld® 37 (E6013) product page.

- Lincoln Electric — Fleetweld® 180 (E6011) product page.

- Pinnacle Alloys — E7018 Datasheet (storage & polarity notes).