When I first started setting up my home welding setup, I thought grabbing a cheap machine and striking an arc would be enough — but the reality hit me quick. Between figuring out whether MIG or TIG was the better choice, how to prep joints on different metal thicknesses, and which filler rods actually worked for stainless vs mild steel, I spent more time troubleshooting than welding.

Like many beginners, I struggled with controlling the arc and burning through thin metal, not realizing that proper setup is just as important as technique. Getting the right machine, learning gas vs flux-core options, and understanding how amperage settings affect penetration and weld strength makes all the difference for both safety and quality.

If you’ve ever been confused about where to start, you’re not alone — and that’s exactly why I’ve put this guide together, so you can skip the frustration and build a reliable shop setup that lets you weld with confidence.

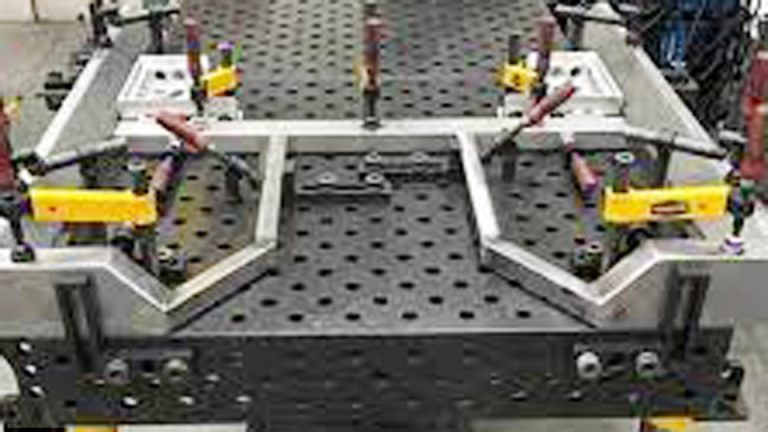

Image by thefabricator

Why a Home Welding Setup Matters

Starting with a proper setup isn’t just about convenience—it’s about safety and quality. Welding involves intense heat, bright arcs, and sometimes toxic fumes. Without the right gear, you’re risking burns, eye damage, or weak welds that fail when it matters most. For DIYers, a home setup means you can tackle projects like fixing lawnmowers or building furniture without relying on a pro.

For students or pros, it’s a chance to practice techniques and experiment with materials. Plus, a well-thought-out setup saves you from wasting money on tools that don’t suit your needs. I’ve learned this the hard way—buying a cheap welder that couldn’t handle thicker steel was a costly lesson.

Choosing the Right Welding Process

Your home welding setup starts with picking a welding process that matches your goals. The main options for beginners are MIG, Stick, and TIG. Each has its strengths, and your choice depends on what you’re welding, your budget, and how much time you want to spend learning.

MIG Welding: The Beginner’s Best Friend

MIG (Metal Inert Gas) welding is my go-to recommendation for most beginners. It uses a wire fed through a gun, with a shielding gas like argon or CO2 to protect the weld. It’s versatile, relatively easy to learn, and great for automotive repairs, light fabrication, or DIY projects like building a workbench.

How it works: A continuous wire electrode feeds through the welding gun, creating an arc that melts the wire and the base metal to form the weld. The shielding gas keeps oxygen and contaminants away, ensuring a clean weld.

When to use it: MIG is perfect for welding steel, stainless steel, or aluminum (with the right setup). It’s ideal for thin to medium-thick materials, like car panels or ¼-inch steel plates.

Practical tips:

Settings: Start with your machine’s chart for voltage and wire speed. For 1/8-inch steel, try 18-20 volts and a wire speed of 250-300 inches per minute (IPM). Adjust until you get a steady “bacon sizzle” sound.

Mistakes to avoid: Don’t skip cleaning the metal—rust or oil will cause porosity (holes in the weld). I once rushed a project and ended up with a weld that looked like Swiss cheese.

Pro tip: Use a 75/25 argon/CO2 mix for steel. It’s forgiving and produces smooth welds.

Stick Welding: Rugged and Reliable

Stick welding (Shielded Metal Arc Welding, or SMAW) is old-school but tough. It uses a flux-coated electrode (the “stick”) to create the weld, and no external gas is needed, making it great for outdoor work.

How it works: The electrode carries the current, and its flux coating creates a shielding gas when it burns, protecting the weld. You strike an arc, move the electrode along the joint, and replace it when it burns down.

When to use it: Stick is ideal for heavy-duty repairs, like fixing farm equipment or welding thick steel (1/4-inch and up). It’s also good for windy or dirty conditions since it doesn’t rely on gas.

Practical tips:

- Settings: For a 1/8-inch 6011 electrode on 1/4-inch steel, set your machine to 90-120 amps (DCEN for most rods). Adjust based on the rod’s specs.

- Mistakes to avoid: Striking an arc can be tricky. Practice on scrap metal to avoid sticking the rod to the workpiece, which I did plenty as a beginner.

- Pro tip: Keep your rods dry in a sealed container. Wet rods cause erratic arcs and poor welds.

TIG Welding: Precision for the Patient

TIG (Tungsten Inert Gas) welding is the most precise but has a steep learning curve. It uses a non-consumable tungsten electrode and a separate filler rod, with shielding gas to protect the weld.

How it works: You hold a torch with a tungsten electrode and feed a filler rod by hand. The arc melts the base metal and rod, creating a precise weld pool.

When to use it: TIG is best for thin materials, stainless steel, or aluminum, like custom fabrication or art projects. It’s not ideal for beginners due to the skill required, but it’s worth learning later.

Practical tips:

Settings: For 1/16-inch aluminum, try 60-80 amps (AC for aluminum, DCEN for steel). Use pure argon gas.

Mistakes to avoid: Don’t let the tungsten touch the weld pool—it’ll contaminate the weld. I ruined a few tungsten tips before I got the hang of it.

Pro tip: Practice hand coordination on scrap before tackling a real project. It’s like learning to pat your head and rub your stomach.

Comparison Table: Welding Processes for Beginners

| Process | Best For | Pros | Cons | Beginner-Friendly? |

|---|---|---|---|---|

| MIG | Automotive, light fabrication | Easy to learn, fast, versatile | Needs gas, less portable | Yes |

| Stick | Heavy repairs, outdoor work | No gas needed, durable | Steeper learning curve | Moderate |

| TIG | Precision, aluminum | Clean, precise welds | Hard to master, slow | No |

Picking Your Welding Machine

Your welder is the heart of your setup. For a home shop, you want something reliable, beginner-friendly, and within budget. Here’s what to consider.

Key Features to Look For

Ease of Use: Look for machines with clear controls and auto-settings. MIG welders like the Hobart Handler 140 are great for beginners due to their simplicity.

Versatility: Multi-process welders (MIG/Stick/TIG) give you room to grow. The YesWelder MP200 is a solid budget option.

Power Requirements: Most home shops use 110V outlets, but 220V machines offer more power for thicker materials. Check your garage’s electrical setup.

Safety Features: Thermal overload protection prevents overheating—a lifesaver for long sessions.

My Recommendations

- MIG: Hobart Handler 140 ($600-$700). It’s reliable, portable, and handles 1/4-inch steel with ease.

- Stick: Lincoln Electric K1170 ($300-$400). Compact and great for small repairs.

- Multi-Process: YesWelder MP200 ($800-$900). Affordable and versatile for learning multiple processes.

Don’t buy the cheapest welder on Amazon. I tried a $200 no-name machine once, and it died after a month of light use. Invest in quality.

Essential Tools and Supplies

Beyond the welder, you’ll need tools and supplies to make your setup functional and safe. Here’s what I keep in my shop.

Must-Have Tools

- Welding Helmet: A good auto-darkening helmet (shade 9-13) protects your eyes. The Lincoln Viking 3350 is comfortable and reliable.

- Gloves: Flame-resistant gloves prevent burns. I like leather gloves with a cotton lining for dexterity.

- Safety Glasses: Wear these under your helmet to protect from debris.

- Angle Grinder: For cleaning metal and grinding welds. A 4.5-inch DeWalt grinder is a workhorse.

- Clamps: C-clamps and magnetic clamps hold your workpieces steady.

- Wire Brush and Chipping Hammer: For cleaning slag and spatter.

Filler Metals and Electrodes

Your choice of filler metal depends on the process and material.

- MIG Wire: ER70S-6 (0.030-inch) is a go-to for steel. It’s forgiving and works for most projects.

- Stick Electrodes:

- 6011: Versatile, good for rusty or dirty metal.

- 7018: Strong welds for clean steel, but needs dry storage.

- TIG Filler Rods: ER70S-2 for steel, ER4043 for aluminum.

Pro tip: Buy small quantities of electrodes to test what works best. I wasted money on a bulk pack of 6013 rods that didn’t suit my projects.

Safety First: Protecting Yourself and Your Shop

Welding is rewarding but dangerous if you’re careless. I’ve seen guys skip safety gear and end up with arc burns or worse. Here’s how to stay safe.

Protective Gear

Helmet: Always use an auto-darkening helmet with a proper shade. Fixed-shade helmets are cheaper but less versatile.

Clothing: Wear flame-resistant long sleeves, pants, and steel-toe boots. Cotton or leather is best—synthetic fabrics melt.

Respirator: If you’re welding indoors, a respirator protects against fumes, especially with galvanized steel.

Shop Safety

- Ventilation: Weld in a well-ventilated area or use an exhaust fan. I learned this after coughing through a session welding galvanized pipe.

- Fire Prevention: Keep a fire extinguisher nearby. Clear flammable materials like wood or rags from your workspace.

- Grounding: Ensure your welder is properly grounded to avoid shocks.

Mistake to avoid: Don’t weld near flammable liquids. I once sparked near a gas can—thankfully, nothing caught fire, but it was a wake-up call.

Setting Up Your Workspace

Your home shop doesn’t need to be fancy, but it should be functional. Here’s how to set it up.

Space Requirements

Size: A 10×10-foot area works for small projects. Ensure you have room to move around your workpiece.

Surface: Use a sturdy metal welding table. I built mine from 1/4-inch steel plate and angle iron for under $100.

Lighting: Bright overhead lights help you see your work. Avoid welding in dim conditions—it’s hard to spot defects.

Electrical Setup

- Power: Most beginner welders run on 110V, but check your breaker capacity. A 20-amp circuit is usually enough for MIG.

- Extension Cords: Use heavy-duty, 12-gauge cords to avoid voltage drops.

Pro tip: Label your tools and keep them organized. I spent hours searching for a misplaced chipping hammer early on.

Step-by-Step Guide to Your First Weld

Ready to weld? Here’s a simple guide for a MIG butt weld on 1/8-inch steel.

- Prep the Metal: Clean both pieces with a wire brush or grinder to remove rust, paint, or oil.

- Set Up the Welder: Install 0.030-inch ER70S-6 wire and a 75/25 argon/CO2 gas mix. Set voltage to 18-20V and wire speed to 250-300 IPM.

- Clamp the Pieces: Align the edges tightly with clamps to minimize gaps.

- Tack Weld: Make small welds every few inches to hold the pieces together.

- Run the Bead: Hold the gun at a 10-15° angle, moving steadily along the joint. Aim for a consistent “sizzle” sound.

- Clean the Weld: Use a wire brush to remove spatter and check for defects like porosity.

Don’t rush the bead. Moving too fast causes weak, narrow welds. Practice on scrap to get the rhythm.

Common Beginner Mistakes and Fixes

Every welder messes up starting out. Here are some I made and how to fix them.

- Porosity (Holes in Weld): Caused by dirty metal or improper gas flow. Clean thoroughly and check your gas regulator (20-25 CFH for MIG).

- Sticking Electrodes (Stick Welding): You’re too close or using too low an amperage. Increase amps or practice striking the arc.

- Burn-Through: Too much heat on thin metal. Lower your voltage/amps or move faster.

My first MIG weld looked like a lumpy caterpillar because I didn’t clean the metal. A quick grind and re-weld fixed it, but I learned to prep properly.

Material Compatibility and Filler Selection

Matching your filler to the base metal is crucial for strong welds. Here’s a quick guide.

Mild Steel: Use ER70S-6 wire (MIG) or 6011/7018 rods (Stick). These are versatile and forgiving.

Stainless Steel: Use 308L wire or rods for most grades. Ensure your machine supports stainless settings.

Aluminum: Use ER4043 wire (MIG) or rods (TIG) with pure argon gas. Clean aluminum thoroughly to remove oxide layers.

Pro tip: For mixed metals, consult a welding chart or expert. I once tried welding stainless to mild steel with the wrong rod—big mistake.

Budgeting for Your Setup

A beginner’s setup can cost $500-$1,500, depending on your goals. Here’s a rough breakdown:

- Welder: $300-$800

- Helmet: $100-$200

- Gloves, jacket, safety glasses: $50-$100

- Tools (grinder, clamps, etc.): $100-$200

- Consumables (wire, rods, gas): $50-$200

Start with a used welder from a reputable brand like Miller or Lincoln to save money. Check for warranties or return policies.

Maintaining Your Equipment

Keep your welder and tools in top shape to avoid downtime.

- Clean the Welder: Remove dust and spatter from the machine regularly.

- Check Consumables: Replace worn contact tips (MIG) or electrodes promptly.

- Store Properly: Keep rods and wire in a dry, sealed container to prevent rust.

Anecdote: I once left my MIG wire exposed, and humidity rusted it overnight. It caused erratic feeding and bad welds until I replaced it.

Conclusion: You’re Ready to Weld

Setting up a home welding shop as a beginner is a big step, but with the right gear, process, and safety know-how, you’re ready to tackle projects with confidence. Whether you’re fixing a gate, building a sculpture, or learning for a career, your setup is your foundation. Start with MIG for ease, invest in quality safety gear, and practice on scrap to hone your skills. You’ll make mistakes—everyone does—but each one teaches you something new.

FAQ

What’s the easiest welding process for beginners?

MIG welding is the easiest for beginners. It’s forgiving, versatile, and requires less hand-eye coordination than Stick or TIG. Start with a machine like the Hobart Handler 140 and practice on mild steel.

How much does a beginner welding setup cost?

A basic setup costs $500-$1,500, including a welder, helmet, gloves, and tools. You can save by buying used equipment from trusted brands, but prioritize safety gear.

Can I weld in my garage safely?

Yes, if you ventilate well, clear flammable materials, and use proper protective gear. Keep a fire extinguisher handy and ensure your welder is grounded.

What’s the best electrode for Stick welding beginners?

6011 electrodes are great for beginners. They’re versatile, work on dirty or rusty metal, and are easier to strike than 7018 rods.

Do I need a 220V outlet for welding?

Not always. Many beginner welders, like the Hobart Handler 140, run on 110V. For thicker materials, a 220V machine offers more power, so check your shop’s electrical setup.

[…] Use supports or fixtures to stabilize small parts; a jig can improve repeatability and quality. See also my beginner home welding setup. […]