When I first started MIG welding aluminum, I was surprised by how often that stubborn black smut would show up around my welds. At first, I blamed my technique or the filler wire, but I soon realized that smut when MIG welding aluminum is one of the most common frustrations welders face. Whether it’s from poor joint prep, the wrong shielding gas mix, or not having proper arc control, aluminum is far less forgiving than stainless or mild steel.

The oxide layer, metal thickness, and even the heat input all play a big part in how clean your weld turns out. And it’s not just about appearance—too much smut can weaken weld quality, increase finishing time, and raise overall project costs. If you’ve been wondering how to reduce smut and get cleaner, stronger MIG welds on aluminum, this guide will walk you through proven, shop-tested solutions.

Image by reddit

What Causes Smut in MIG Welding Aluminum

Smut is that black, powdery residue you see coating your weld bead and the surrounding metal after MIG welding aluminum. It’s essentially oxidized aluminum and magnesium particles that evaporate in the intense heat of the arc and then condense as soot. I’ve seen it ruin otherwise perfect welds on everything from boat repairs to aerospace parts.

The main culprit? Poor shielding gas coverage. When your argon isn’t blanketing the weld pool properly, those vapors mix with oxygen in the air and form oxides. Filler wires with high magnesium content, like 5356, make it worse because magnesium boils off easier than aluminum.

I remember one job where I was welding aluminum brackets for a trailer—switched to a lower-magnesium wire, and the smut dropped by half. Other causes include contaminants on the surface, like oils or old oxides, and even drafts in your shop pulling air into the arc.

Why does this matter in the real world? Beyond the aesthetics, excessive smut can compromise weld strength. It might mask porosity or inclusions that could fail under load, especially in structural applications following US codes like AWS D1.2 for aluminum.

For DIYers, it means more post-weld grinding, which risks thinning your material. Pros know it eats into productivity—time is money on the job site. Safety-wise, inhaling that fine dust isn’t great, so always wear your respirator.

Preparing Your Aluminum Workpiece to Minimize Smut

Prep work is where most smut problems start, and it’s the easiest fix. Aluminum loves to form a tough oxide layer that’s like a barrier to good fusion. If you don’t clean it off, it’ll vaporize in the arc and turn into smut. I’ve burned through so many brushes learning this.

First, degrease the surface. Use a solvent like acetone or a dedicated aluminum cleaner on a clean rag—avoid shop towels with lint or residues. Wipe down both sides if it’s thin stock. Then, grab a stainless steel wire brush dedicated to aluminum only; cross-contaminating with steel particles is a rookie mistake that leads to rust spots later.

For thicker oxides, like on older stock, I sometimes use a chemical etchant, but that’s overkill for most jobs. Just brush until you see bright metal. Do this right before welding—aluminum re-oxidizes fast in humid US shops. If you’re in a coastal area like Florida, store your material indoors to avoid moisture buildup.

Joint prep is key too. Bevel edges on thicker pieces, say over 1/4 inch, for better penetration. A 60-degree V-groove works well for butt joints. This dilutes the base metal in the weld pool, reducing crack risks and smut from uneven heating. For lap joints, ensure tight fit-up; gaps suck in air and amp up oxidation.

One personal tip: Preheat if your aluminum is cold from storage. A gentle 100-150°F with a torch evens out the heat and cuts down on condensation-related smut. But don’t overdo it—too hot, and you’ll soften the metal, especially 6xxx series alloys common in extrusions.

Choosing the Right Filler Wire and Shielding Gas

Picking the right consumables is like choosing the right tool for the job—it makes everything smoother. For MIG welding aluminum, your filler wire and gas directly impact smut levels.

Start with filler wire. 4043 is my go-to for less smut because it’s silicon-based with no magnesium, so less vaporization. It’s fluid, great for out-of-position work, and forgives minor contaminants. But if you need more strength, like on 5xxx series marine aluminum, go with 5356— just expect more smut and plan for it. Diameter-wise, 0.035-inch wire feeds reliably on most machines.

I’ve had jobs where switching from 5356 to 4043 turned a sooty mess into shiny beads. But check compatibility—4043 isn’t ideal for anodizing later, as it can discolor.

Shielding gas is non-negotiable: 100% argon for most aluminum MIG. It provides stable arc and good coverage. Helium mixes (75/25 argon/helium) add heat for thicker material but can increase smut if your flow isn’t dialed in. Aim for 20-30 cubic feet per hour (CFH)—too low, and shielding fails; too high, and turbulence pulls in air.

Pro tip: Use a gas lens on your torch for better diffusion. It spreads the gas evenly, cutting smut on fillets or corners. And always purge your lines before starting to flush out moisture.

Here’s a quick comparison table of common fillers:

| Filler Wire | Pros | Cons | Best For | Smut Level |

|---|---|---|---|---|

| 4043 | Low smut, good fluidity, crack-resistant | Lower strength, not for high-magnesium bases | General fabrication, automotive | Low |

| 5356 | High strength, good corrosion resistance | More smut, less forgiving on contaminants | Marine, structural | Medium-High |

| 5556 | Balanced strength, weldability | Moderate smut, pricier | High-stress applications | Medium |

This table has saved me time matching wires to jobs.

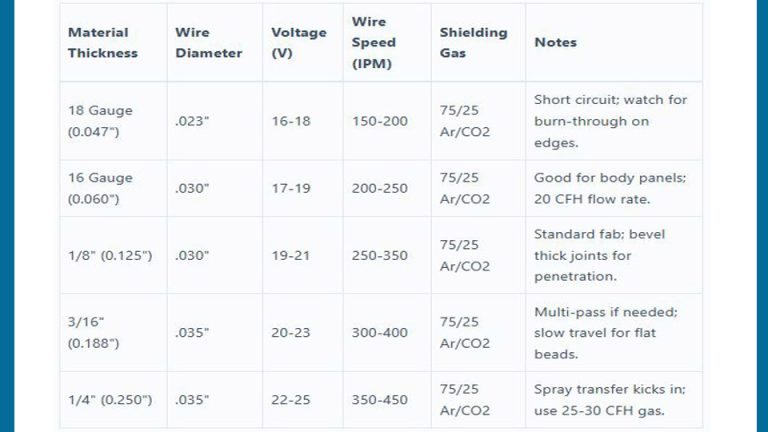

MIG Welder Settings for Reducing Smut on Aluminum

Settings can make or break your weld. Too hot, and you boil off more metal into smut; too cold, and you get poor fusion. I’ve tinkered endlessly on my Lincoln Power MIG to get this right.

Voltage: Start at 18-22 volts for 1/8-inch aluminum with 0.035 wire. Higher voltage widens the arc, increasing smut from more evaporation. Wire feed speed: 300-400 inches per minute (IPM) pairs well. Test on scrap—adjust until the arc sounds like frying bacon, not popping.

Amperage follows automatically on most synergic machines, but aim for 100-150 amps on thin stock. For spool guns, which I love for portability, keep stickout at 3/8-1/2 inch to avoid burnback.

Polarity is DCEP (reverse) for aluminum—straight polarity won’t clean the oxides. Drive rolls: U-groove only, not V, to prevent shaving the soft wire.

One anecdote: On a fence repair job, I cranked voltage too high and got smut everywhere. Dropped it by 2 volts, and it cleaned up. Always start conservative and ramp up.

For push-pull feeders, tension just enough to feed without slipping. Loose tension causes erratic feeding, leading to gas gaps and smut.

Welding Techniques That Help Reduce Smut

Technique is where experience shines. Push, don’t pull—that’s rule one. Pushing puts the arc’s cleaning action ahead of the puddle, etching away oxides before they cause trouble. Pulling drags smut behind.

Gun angle: 10-15 degrees push. Too steep (over 20 degrees) creates a venturi effect, sucking air in and blackening the weld. I’ve fixed this mid-job by shallowing my angle.

Travel speed: Steady and moderate. Too slow overheats, vaporizing more metal; too fast causes lack of fusion. Aim for 10-15 IPM on flat welds.

For fillets, angle the gun toward the vertical piece to direct heat evenly. On laps, weave slightly if needed, but straight stringers minimize smut.

Cup-to-work distance: Keep it under 5/8 inch. Longer lets air in. In windy job sites, use wind blocks or increase gas flow slightly.

Out-of-position: Vertical up for thick stuff—gravity helps control the puddle, reducing smut buildup. Horizontal is fine for thinner.

Common fix: If smut appears on one side, tweak your angle across the joint. It moves the soot around until it’s minimal.

Post-Weld Cleanup and Smut Removal

Even with perfect technique, some smut might linger. Don’t grind immediately—let it cool to avoid smearing.

Brush it off with a stainless wire wheel on an angle grinder. For stubborn spots, a scotch-brite pad works without removing metal. Avoid steel tools to prevent contamination.

If it’s bad, a mild acid pickle like diluted nitric can dissolve oxides, but rinse thoroughly and neutralize—safety first, gloves and ventilation.

In my shop, I keep a dedicated aluminum cleanup station. It saves time and keeps welds looking pro.

Common Mistakes That Lead to Excessive Smut and How to Fix Them

We’ve all been there—rushing a job and paying for it with soot. Top mistake: Skipping cleaning. Fix: Make it routine, even on “clean” stock.

Wrong wire: Using 5356 on everything. Fix: Match to base metal per AWS charts.

Poor gas: Leaks or low flow. Fix: Check hoses, use flowmeter, no drafts.

Dragging the gun. Fix: Practice pushing on scrap.

Contaminated wire: Old spools with oxides. Fix: Store sealed, use fresh.

Overheating: High settings. Fix: Dial back, test beads.

One story: A trainee dragged on an aluminum tank repair—smut city. Switched to push, problem solved. Learn from mistakes, don’t repeat them.

Key Takeaways and Why You’re Ready to Weld Cleaner Aluminum

Reducing smut when MIG welding aluminum boils down to solid prep, smart consumables, dialed-in settings, and push technique. Clean your metal, choose low-magnesium wire when possible, shield with pure argon, and keep that gun angle right. Do this, and you’ll cut cleanup time, improve weld strength, and avoid costly reworks—whether you’re fabbing a custom rack in your garage or meeting deadlines on site.

You’re now armed with the know-how I wish I had starting out. Grab your gear, test on scrap, and weld with confidence. Pro tip: Always weld a sample bead first—it reveals issues before they ruin your project.

Is Smut Dangerous in Aluminum Welds?

Not directly, but it can hide defects like cracks or porosity that compromise safety. Plus, the dust is an inhalation hazard—always use PPE.

What’s the Best Shielding Gas for MIG Welding Aluminum?

100% argon is standard for stability and low smut. Add helium for thicker material needing more heat, but monitor for increased oxidation.

Can I MIG Weld Aluminum Without a Spool Gun?

Yes, with a push-pull feeder or standard setup, but spool guns reduce feeding issues on soft wire, leading to fewer gas interruptions and less smut.

Why Does My Aluminum Weld Turn Black?

Usually poor shielding—check gas flow, drafts, or gun distance. Also, high-magnesium fillers or contaminants amplify it.

How Do I Choose Between 4043 and 5356 Filler Wire?

Go 4043 for less smut and easier welding on general alloys. Use 5356 for better strength on 5xxx bases, but expect more cleanup.