first time my MIG welder started sputtering and feeding wire like it had a mind of its own. At first, I blamed the wire spool, then the contact tip, even messed with the tensioner — but the real culprit was a worn-out MIG gun liner. A lot of welders, whether you’re just starting out or you’ve burned miles of bead, run into the same issue: poor wire feed, bird-nesting, or inconsistent arc control that makes laying down a clean weld almost impossible.

Replacing the MIG gun liner sounds intimidating, but it’s actually one of the simplest fixes you can do — and it has a huge impact on weld quality, whether you’re running mild steel, stainless, or even comparing MIG vs TIG work.

A fresh liner keeps your filler wire flowing smoothly, which means less downtime, better penetration on thicker metals, and stronger joints that won’t fail under stress. In this guide, I’ll walk you through how to replace a MIG gun liner step by step, with shop-tested tips that save you time, money, and frustration.

Image by thefabricator

What Is a MIG Gun Liner and Why Does It Wear Out?

You’re running a solid MIG setup on your Miller or Lincoln machine, shielding gas flowing, voltage dialed in just right. At the heart of that smooth operation is the MIG gun liner—a thin, flexible tube that guides your welding wire from the drive rolls all the way to the contact tip. It’s like the unsung hero of the conduit, keeping that wire straight and protected from kinks or bends that could snag it up.

Most liners are made from steel, nylon, or even aluminum, each with its own vibe depending on your wire size and material. Steel’s tough for heavy-duty stuff like .045 wire on structural steel, nylon’s slick for aluminum to cut down on friction, and hybrids mix it up for versatility. They snake through the gun’s cable—sometimes 10, 15, or 25 feet long—and their job is simple: deliver wire consistently so your arc stays stable.

But here’s the rub—they wear out. I’ve swapped hundreds over the years, and it always hits when you’re switching from mild steel to stainless or cranking up the amps for thicker plates. Friction from the wire rubbing inside, especially with knurled drive rolls gripping too hard, chews ’em up.

Dirty wire—think rust from a humid shop or mill scale—accelerates it, turning a liner’s life from months to weeks. Heat buildup near the tip warps them too, and if you’ve ever dragged your gun across a concrete floor (guilty as charged), a kink can spell doom fast.

In my early days as a fab shop apprentice, I ignored a gritty feed for a whole shift, thinking it was just the wire spool. Ended up with a bird’s nest so bad it jammed the feeder—lost two hours cleaning it. Lesson learned: The liner’s your wire’s lifeline. Keeping it fresh means cleaner welds, less downtime, and that satisfying “zip” when the wire pays out smooth.

Signs Your MIG Gun Liner Is on Its Last Legs

You don’t always catch it right away, but your machine’s got tells. The first red flag? Erratic wire feeding. If you’re pushing the trigger and the wire stutters or stops midway, like it’s hitting a wall, that’s classic liner wear. I’ve seen it on everything from hobbyist Harbor Freight rigs to beefy industrial Millermatics—doesn’t discriminate.

Another giveaway: Bird nesting at the drive rolls. That tangled mess of wire bunching up behind the rollers? Often the liner’s too worn or kinked, letting the wire wander instead of staying guided. Or check for burn-backs, where the wire welds itself to the tip. If it’s happening more than once a blue moon, even with good settings, blame the liner for inconsistent delivery.

Resistance is a big one too. Unload your drive rolls and try feeding wire by hand from the spool—if it drags like sandpaper, the liner’s inner diameter is compromised. And listen: A healthy setup hums quietly; a dying liner chatters or whines as the wire fights through burrs.

Last job site story: We were framing a steel staircase, .030 wire on 14-gauge, and the feed kept faltering. Thought it was tension at first, but nope—pulled the liner, and it was scored like a scratched record from some flux-cored debris. Swapped it mid-morning, and the rest of the day flew. Pay attention to these signs early; they’re your cue to act before a small annoyance turns into a shop-stopper.

Choosing the Right MIG Gun Liner for Your Welding Needs

Not all liners are created equal, and picking the wrong one can turn a good weld day bad. Start with your wire size—that .030, .035, or .045 dictates the inner diameter. Too tight, and friction builds fast; too loose, and the wire wanders, causing arc wander.

Material matters too. For mild steel or stainless, steel liners hold up like champs, especially in high-amperage runs. Nylon’s my go-to for aluminum—it’s low-friction, resists corrosion, and feeds silky on thinner gauges. If you’re doing a mix, like fab work with both solid and flux-core, look for V-groove or U-groove options that match your drive rolls.

Length? Match your cable—overlong ones bunch up, short ones leave gaps. And don’t sleep on brands: Bernard, Tweco, or Lincoln originals fit like gloves on US machines, while generics might save a buck but wear quicker.

Here’s a quick comparison to help you decide:

| Liner Type | Best For | Pros | Cons | Typical Cost (US) |

|---|---|---|---|---|

| Steel | Mild steel, high amps (.035-.045 wire) | Durable, affordable, great for straight runs | Higher friction on aluminum, can rust if exposed | $8-15 |

| Nylon | Aluminum, stainless (.030-.035 wire) | Low friction, flexible, corrosion-resistant | Less durable in heat, can kink easier | $10-20 |

| Aluminum | Lightweight setups, long cables | Super smooth feed, lightweight | Softer, wears faster on abrasive wires | $12-18 |

| Hybrid (e.g., Teflon-lined) | Mixed materials, flux-core | Versatile, reduced static buildup | Pricier, may need frequent swaps | $15-25 |

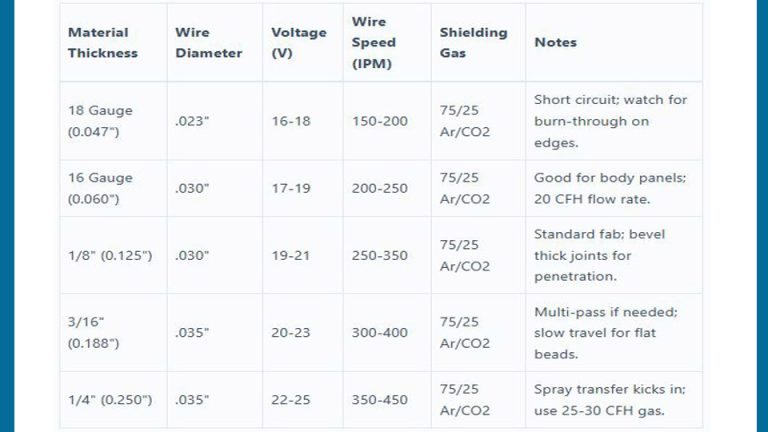

Pro tip from the field: If you’re a hobbyist on a budget, start with nylon for versatility—I’ve run it on everything from bike frames to truck bumpers without a hitch. Pros, match it to your codes; AWS D1.1 calls for consistent feeds to hit those fusion specs. Test a new one on scrap first—dial your voltage to 18-22V for .035, wire speed 250-350 IPM, and see if it arcs clean.

Tools and Materials You’ll Need for a Smooth MIG Liner Swap

Before you dive in, gather your kit—nothing worse than midway through with a dull cutter. Basics: A fresh liner (sized right), wire cutters or side snips for steel/nylon, maybe a hacksaw for tough ones. You’ll need a 10mm wrench for most liner locks, pliers for pulling, and an Allen key set for set screws.

Don’t forget deburring—emery cloth or a belt sander keeps ends clean. Compressed air (100 PSI nozzle) blasts out debris, and anti-spatter spray lubes things up. For safety, gloves, eye pro, and unplug that machine—I’ve zapped myself more than once forgetting that.

Materials-wise, snag new contact tips and nozzles while you’re at it; they’re cheap insurance. And Loctite for set screws—blue threadlocker keeps things from backing out mid-weld.

In my mobile rig, I keep a $20 Harbor Freight liner kit handy: cutters, wrenches, and a trim guide. Saved me on a remote site when the feed went south—five minutes later, back to laying beads.

Step-by-Step Guide: How to Replace Your MIG Gun Liner Like a Pro

Alright, let’s get hands-on. This is for a standard Bernard or Miller-style gun, but the principles hold across US brands. Clear your bench, lay the cable straight—no twists, or you’ll fight it all day. Unplug the welder, purge gas, and let’s roll.

Prep Your MIG Gun for Liner Removal

Start by pointing the gun nozzle down—gravity’s your friend. Remove the nozzle (usually a quick twist or wrench), then the contact tip with channel locks or the tip wrench. Unscrew the gas diffuser if it’s in the way. Now, at the feeder end, loosen the liner lock or set screw—counterclockwise with that 10mm wrench. If it’s stubborn, a shot of penetrating oil loosens it.

Gently pull the old liner from the back. If wire’s stuck (happens with burn-backs), crimp and yank carefully—I’ve used needle-nose pliers to grip without mangling the conduit. Blow air through both ends to clear junk; you’ll be shocked at the grit that puffs out.

Anecdote time: First solo swap, I yanked too hard and kinked the new conduit. Slow and steady—rotate as you pull.

Selecting and Inserting the New Liner

Grab your new liner—feed it into the power pin or feeder adapter first. With the cable dead straight on the floor, push it through using short, firm strokes. No rushing; long pushes kink it like a garden hose. If it binds, twist clockwise gently—nylon glides easier than steel.

For longer guns (15+ feet), grab a buddy to steady the far end. Once it pokes out the nozzle, mark the excess. Pro move: Use the old liner as a template for length.

Trimming and Fitting the Liner Perfectly

Here’s where precision pays. Account for tip setback: 1/8-inch for solid wire, 3/8 for flux-core. Cut flush to the nozzle first with sharp snips—dull ones burr the end, snagging wire forever.

Pull it back, hold against the tip (chamfered end first), and trim to setback length. Deburr with sandpaper—square ends cause drag. For nylon, a 60-degree chamfer tool bevels it nice; steel just needs a light file.

Reinsert: Feed until it seats in the feeder, no gaps. Tighten the lock clockwise—snug, not Hercules. Reinstall diffuser, tip, nozzle. Test-feed wire by hand; it should glide like butter.

Full run-through took me 15 minutes after practice. Settings check: For .035 on 1/4-inch plate, 20V, 300 IPM—arc should be steady, no spits.

Final Checks and Test Weld

Before firing up, visually inspect: Liner flush? No burrs? Tighten set screws with Loctite. Load wire, set tension so rolls slip lightly—pinch test: Wire balls in your hand, doesn’t elongate.

Purge gas, strike an arc on scrap. Listen for smooth feed, watch for even melt pool. If it’s off, re-trim—that 1/16-inch matters.

I’ve botched this on a rush job, trimming short—wire wandered, arc fluttered. Double-check, and you’re golden.

Common Mistakes When Replacing a MIG Liner (and How to Avoid Them)

We all screw up—it’s how we learn. Top blunder: Cutting with dull tools. Leaves burrs that shred wire like cheese grater. Fix: Sharpen or replace snips; always deburr post-cut.

Another: Gaps at the feeder or tip. Wire flops around, causes bird nests. Solution: Push liner fully seated, check with a straight edge.

Over-tightening the lock—strips threads or bows the liner. Snug is king; torque to spec (usually 10-15 ft-lbs).

Ignoring cable straightness—twists bind insertion. Lay it out, walk it straight like coiling a rope.

And dirty hands: Grease transfers, gums up the new liner. Wipe down first.

From the shop: Apprentice cut too long once, liner pumped back under pressure—weld city. Measure twice, cut once.

Tips for Maintaining Your MIG Gun Liner After Replacement

Fresh liner? Keep it that way. Blow it out with 120 PSI air every spool change—from nozzle and feeder ends. Anti-spatter spray inside monthly for flux jobs.

Run clean wire—store spools dry, use anti-rust bags. Adjust drive rolls: V-groove for round wire, U for shaped. Tension light—slip test prevents corkscrewing.

For pros: Log swaps in your maintenance sheet; AWS audits love that. Hobbyists, inspect monthly—catches wear early.

My ritual: Post-weld, hang the gun straight, no coiling tight. Extended life by double.

Troubleshooting Other Wire Feeding Issues Tied to the Liner

If post-swap it’s still wonky, check beyond. Burn-back? Voltage too low—bump to 19V. Bird nest? Rolls worn—swap ’em.

Stuck wire? Crank the feeder backward gently, or fish with spare wire. For aluminum, static buildup—ground your bench.

Real fix: .030 stainless feeding rough? Nylon liner, plus silicone lube. Dialed it for a exhaust fab last week—flawless.

Wrapping It Up: You’re Now Liner-Savvy and Weld-Ready

There you have it—everything from spotting a failing liner to trimming that new one just right. Swapping a MIG gun liner isn’t rocket science, but doing it right turns frustrating feeds into reliable arcs, stronger welds, and more time enjoying the craft. Whether you’re a student nailing your first bead or a fab vet chasing perfection, this fix boosts your efficiency and safety every time.

Listen to your machine’s cues, match liner to wire, and maintain like it’s your daily driver. You’re more prepared now—confident in the shop or garage, tackling projects without the drama. Go ahead, grab that liner and swap it today; your next weld’s gonna sing. Keep a spare in your toolbox—trust me, it’ll bail you out at 2 a.m. on that “quick” trailer repair.

What Size MIG Liner Do I Need for .035 Wire?

For .035 wire, go with a .052-inch inner diameter liner—steel for mild, nylon for aluminum. It gives just enough clearance without slop, feeding smooth at 250-350 IPM.

How Often Should I Replace My MIG Gun Liner?

Depends on use: Hobbyists every 3-6 months or 10 spools; pros weekly in dirty environments. Watch for feed resistance—don’t wait for total failure.

Can I Reuse an Old MIG Liner After Cleaning?

Sometimes, if it’s just dirty—blow it out, deburr ends. But wear shows as scoring; better safe with new for $10. I’ve salvaged a few, but fresh is foolproof.

Why Is My New MIG Liner Kinking During Installation?

Cable’s twisted or you’re pushing too hard. Lay it straight, use short strokes, twist clockwise. For long runs, two-person job.

What’s the Difference Between Steel and Nylon MIG Liners?

Steel handles high heat and abrasion better for steel wires; nylon’s lower friction shines on aluminum, reducing drag and static. Pick based on your primary material.

(Word count: 2,847)