When I first started learning how to set up a MIG welder with gas, I made just about every mistake possible — from cranking the gas flow rate too high to using the wrong wire type for the metal thickness I was working on. It’s easy to underestimate how much the setup itself affects your welds.

Too little shielding gas, and you’ll get porosity; too much, and you’ll waste gas (and money) while creating turbulence that messes with arc control. Whether you’re working on mild steel, stainless, or aluminum, getting the MIG vs TIG settings right — including wire feed speed, voltage, and joint prep — makes all the difference in achieving clean, strong, and spatter-free welds.

Once you understand how to fine-tune your welder and gas setup, it’s like flipping a switch — your welds go from messy to professional in no time. Let’s break down exactly how to dial in your MIG welder for smooth, consistent results every time.

Photo by theweldspace

What Is MIG Welding and Why Use Shielding Gas

MIG welding, or Gas Metal Arc Welding as the pros call it, uses a continuous wire electrode fed through a gun to join metals. The arc melts the wire and base material, forming a puddle that solidifies into a joint. Shielding gas flows around this action, creating a protective bubble that blocks oxygen, nitrogen, and other atmospheric nasties from sneaking in.

Without gas, you’d get oxidation—like rust on steroids in the weld—leading to brittle results or holes that compromise strength. I’ve seen it firsthand: a buddy skipped gas on a quick fix, and the weld popped under load, turning a simple repair into a headache.

Using gas ensures cleaner welds, better penetration, and less cleanup, which is huge for DIYers or fab hobbyists cranking out gates or brackets in the garage. It’s versatile for mild steel, stainless, or even aluminum, and follows US shop standards for material compatibility and safety.

The gas also stabilizes the arc, making it easier to control, especially for students or beginners. Think of it as the invisible shield that lets the heat do its job without interference. In real-world applications, like fabricating truck beds or repairing machinery, this means welds that meet basic AWS guidelines for integrity without fancy certifications.

Essential Equipment for MIG Welding Setup

You’ll need a MIG welder—something like a Miller or Lincoln unit common in US shops, with adjustable voltage and wire speed. The power source converts household current to the right amps for your material thickness.

The MIG gun is your trigger: it feeds wire and gas through a torch handle. Get one with a comfortable grip for long sessions. Wire spools—ER70S-6 for mild steel is a go-to—come in sizes like 0.030 or 0.035 inches; match it to your project. Shielding gas cylinder, regulator, and hose are key; more on that soon.

Don’t forget the ground clamp—it completes the circuit by clamping to your workpiece. Safety gear: auto-darkening helmet, leather gloves, flame-resistant jacket, and boots. In a shop, I always add a fume extractor because even with gas, arcs kick up particles.

For joint prep, a grinder or wire brush keeps metals clean—rust or paint causes contamination. Filler wire compatibility matters; use solid wire with gas, not flux-core unless you’re going gasless. US practices emphasize clean setups to avoid defects, aligning with OSHA safety and efficient workflows.

Safety Considerations Before Starting

Safety first—welding’s no joke, and I’ve patched up enough burns to know. Always work in a ventilated area; shielding gas like argon can displace oxygen, leading to asphyxiation in confined spaces. Set up near an exhaust fan, but not blowing directly on the weld, or it’ll scatter your gas shield.

Wear full PPE: helmet to shield UV rays that can fry your eyes, gloves for heat and spatter, and coveralls to block sparks. Ground the machine properly to prevent shocks—I’ve zapped myself rushing this. Keep flammables away; sparks fly far.

Check for gas leaks with soapy water on connections—bubbles mean trouble. Secure cylinders upright and chained; a falling tank is a missile. Follow US codes like those from OSHA for electrical and gas handling. Turn off the welder when not in use, and never point the gun at yourself. These habits build trust in your setup and keep you welding another day.

Step-by-Step Guide to Setting Up Your MIG Welder

Let’s get hands-on. Start by placing your welder on a stable, non-flammable surface in a clear area. Plug it in, but don’t power up yet.

Preparing the Welder and Installing Wire

Open the side panel and remove the spool cover. Align the wire spool on the hub—feed from the bottom to avoid tangles. Cut the wire end straight, then feed it through the drive rollers. Set the tension just right: too loose, it slips; too tight, it birds-nests. I’ve fixed countless nests from over-tightening—start light and test.

Push the wire into the gun liner until it hits the tip. Power on the machine, trigger the gun to feed wire out the nozzle, then trim excess. For polarity, use DC electrode negative (gun to ground positive) for gas-shielded solid wire—check your manual, as flux-core reverses it.

Connecting the Shielding Gas

Secure the gas cylinder nearby, chained to prevent tipping. Attach the regulator to the cylinder valve—use a wrench, hand-tight plus a quarter turn. Connect the green hose from regulator to welder’s gas inlet.

Open the cylinder valve slowly—full blast can damage the regulator. Set flow to 15-25 CFH (cubic feet per hour) using the regulator knob; that’s about 7-12 liters per minute. Trigger the gun to check flow without welding—listen for steady hiss, no leaks. In windy shops, bump it up slightly, but excess wastes gas and causes turbulence.

Attaching the Ground Clamp and Final Checks

Clip the ground to clean metal on your workpiece or table. Inspect connections: wire smooth, gas flowing, no frays. Power up, set initial voltage and wire speed based on material—say, 18-20 volts and 150-200 inches per minute for 1/8-inch mild steel.

Test on scrap: arc should sound like bacon frying, not popping. Adjust as needed. This setup ensures compatibility and efficiency, straight from job-site basics.

Choosing the Right Shielding Gas for Your Project

Shielding gas isn’t one-size-fits-all. For mild steel, a 75% argon/25% CO2 mix (C25) is king—affordable, stable arc, good penetration. Pure CO2 works for thicker steel but spits more spatter; I’ve used it on farm repairs for deeper welds.

Aluminum needs 100% argon for clean results without porosity. Stainless? Try argon with 2% oxygen for better wetting. Gas choice affects weld integrity: argon-heavy mixes give smoother beads, CO2 boosts penetration but can roughen the profile.

In US shops, suppliers like Airgas stock these; rent a 20-40 cubic foot tank for hobby use. Match gas to wire and base metal—mismatch leads to defects. Cost efficiency: C25 balances performance and price, saving on cleanup.

Adjusting MIG Welder Settings for Optimal Performance

Settings dial in the magic. Voltage controls arc length—higher for thicker metal, but too much burns through thin stuff. Wire speed matches amperage; fast feed for penetration, slow for thin sheets.

Use your machine’s chart: for 16-gauge steel, try 16-18 volts, 100-150 IPM wire. Inductance, if available, softens the arc for less spatter on sheet metal. Personal tip: start conservative, weld scrap, tweak by sound and bead—crisp sizzle means good.

Joint prep: bevel thick edges, clean to bare metal. Filler compatibility: ER70S-6 wire with C25 gas for mild steel shines. These tweaks ensure material compatibility and strong bonds.

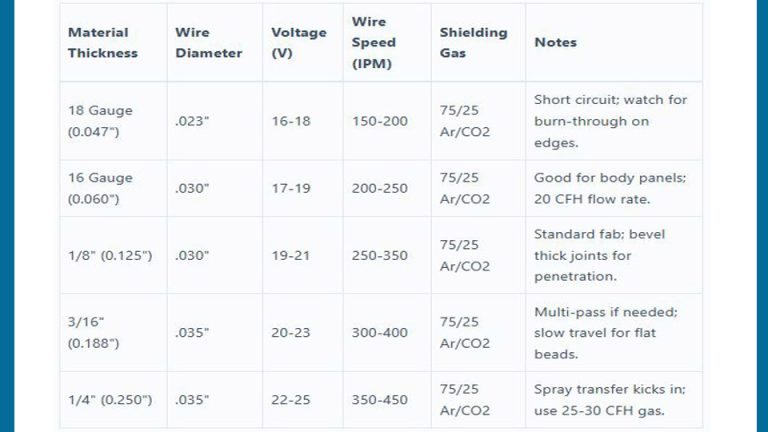

| Material Thickness | Voltage | Wire Speed (IPM) | Gas Flow (CFH) |

|---|---|---|---|

| 1/8 inch | 18-20 | 150-200 | 20 |

| 1/4 inch | 20-22 | 200-250 | 20-25 |

| 16 gauge | 16-18 | 100-150 | 15-20 |

This table’s a quick reference; adjust for your machine.

Common Mistakes When Setting Up MIG Welder with Gas and How to Fix Them

I’ve made ’em all. Wrong gas flow: too low causes porosity—bubbles in the weld like Swiss cheese. Fix: aim 20 CFH, check with a flow tester. Too high? Turbulence sucks in air; dial back.

Birdnesting wire: from poor tension or liner issues—disassemble, clean, lube lightly. Leaky connections waste gas; soap test fixes it fast.

Dirty metal: oil or rust contaminates, leading to cracks. Grind or brush aggressively. Over-tight gun angle: hold 10-15 degrees drag for better shielding. Once, I rushed prep on a frame—weld failed inspection. Lesson: slow down, verify.

Inconsistent settings: voltage too high burns thin metal. Practice on scrap. These fixes boost weld integrity and save frustration.

MIG Welding Techniques for Clean, Strong Welds

Technique seals the deal. Hold 3/8-inch stickout—wire to work distance. Drag or push: drag for penetration on steel, push for aluminum to see the puddle.

Travel speed: steady, not too slow or you overheat. Forehand for flat, backhand for vertical. In shops, we string beads for overlaps, weaving for wider joints.

For hobbyists, start flat—build to overhead. Safety: keep gas coverage by angling right. Real application: auto panels need minimal heat to avoid warp; use pulse if your machine has it.

Pros: fast, versatile. Cons: needs gas supply, sensitive to wind. Compared to stick, less skill for clean results, but gas adds setup.

Applications and Tips for DIY and Professional Welders

DIYers love MIG for trailers, gates—quick, strong. Pros use it in fab shops for structural work, following AWS D1.1 codes for load-bearing.

Tips: preheat thick steel to cut distortion. For cost efficiency, buy wire in bulk, monitor gas use. Students: log settings for each job.

On a job site, wrong gas mix caused porosity in a beam—switched to C25, rewelded clean. Prep and match consumables always.

Conclusion

Setting up your MIG welder with gas boils down to solid prep, right equipment, and tweaks for your material. You’ve got the steps: wire in, gas flowing, settings dialed, techniques practiced. Now you’re geared for welds that last, whether fixing a fence or building a cart. Shielding gas is your weld’s best friend for integrity and safety. Always test on scrap before the real thing—it’ll save your hide and your project.

FAQs

What Gas Should I Use for MIG Welding Mild Steel?

For mild steel, go with a 75% argon and 25% CO2 mix. It gives stable arcs and good penetration without too much spatter, perfect for most shop work.

How Do I Know If My Gas Flow Is Set Correctly?

Trigger the gun without welding— you should hear a steady flow, around 20 CFH. No turbulence or weak hiss means it’s spot on; adjust and check for leaks.

Can I MIG Weld Without Gas?

You can with flux-core wire, but it’s for outdoors or dirty jobs. Gas-shielded gives cleaner, stronger welds indoors—don’t skip it for quality.

What’s the Common Wire Size for Beginners?

Start with 0.030-inch for thin to medium steel. It’s forgiving and feeds smooth; match to your machine’s drive rolls.

Why Is My MIG Weld Porosity Showing Up?

Usually low gas flow or dirty metal letting air in. Clean joints, bump flow to 20-25 CFH, and ensure no drafts blow your shield away.