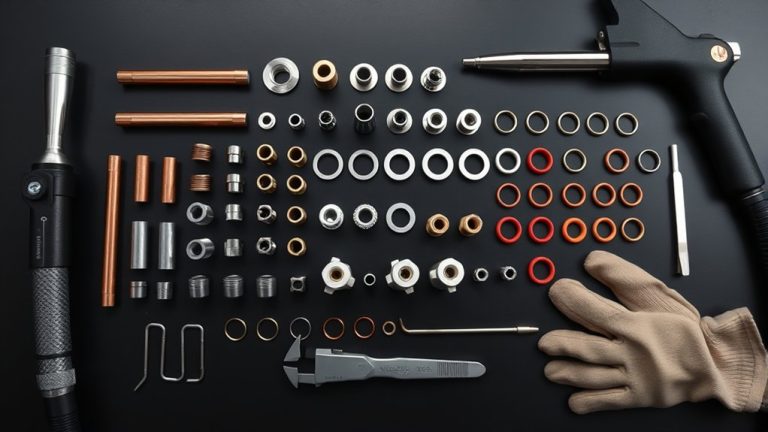

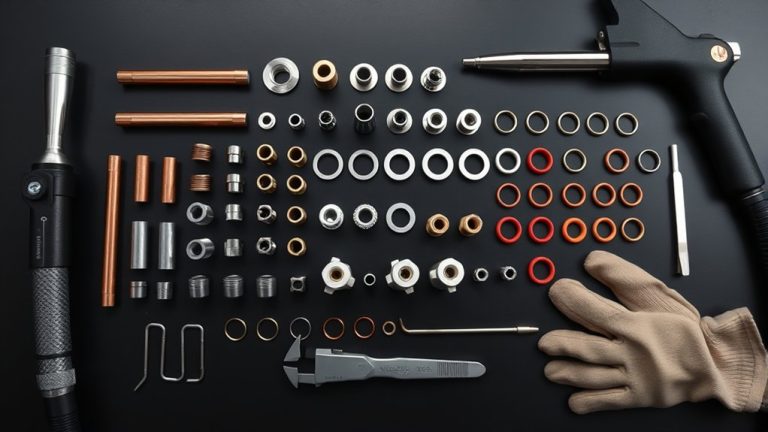

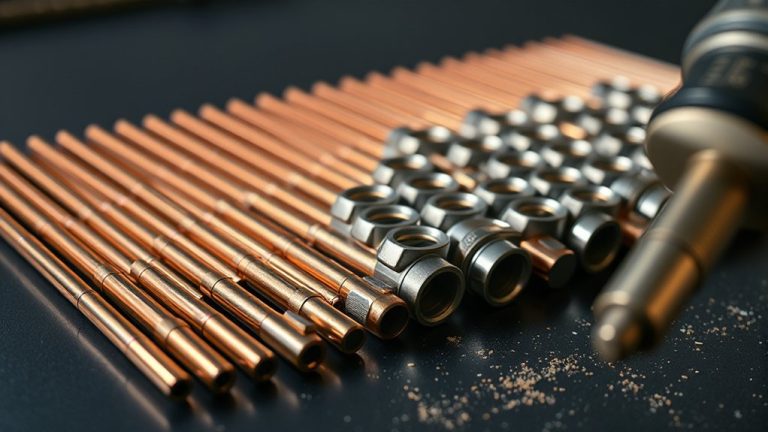

Powermax 125 Consumables Kit: Parts List & Best Practices

Discover the Powermax 125 consumables kit parts, amperage-matching tips, wear limits, and replacement intervals to fix bevel and boost cut quality—ready to dial it in?

Get precise, high-speed metal cutting with a plasma cutter. Choose from portable 110/220V machines to heavy-duty shop units, with options like pilot-arc for cutting through paint or rust, CNC-ready interfaces, and built-in air compressors for true plug-and-play setup. Dial in amperage, air pressure, and torch height for smooth kerf, minimal dross, and tight tolerances on steel, stainless steel, and aluminum. Ideal for fabrication, auto repair, maintenance, and custom projects.

Discover the Powermax 125 consumables kit parts, amperage-matching tips, wear limits, and replacement intervals to fix bevel and boost cut quality—ready to dial it in?

Fuel your Powermax 105 performance with the right consumables—part numbers, setup tips, and dry-fire checks that prevent costly double-arcing—discover the crucial steps next.

Ignite your Powermax 88 potential with compatible consumables, smart alternatives, and upgrade tips—discover which parts maximize cut quality and savings next.

Supercharge your Powermax85 with the right consumables, part numbers, and maintenance tips—discover the exact kits and scheduling secrets that protect cut quality and uptime.

Navigate Powermax 65 consumables like a pro—electrodes, nozzles, shields, and maintenance tips that cut costs and boost quality—discover the exact setups you’re missing.

Crack the Powermax 45XP consumables code—part numbers, setup steps, and critical checkpoints that prevent performance drops—before you risk costly mistakes and downtime.

Step into the industries driving plasma cutting—from automotive to aerospace—and discover surprising use cases that could transform your workflow, but which ones truly fit?

Lean into Fine Cut consumables for cleaner thin‑metal edges; discover tighter kerf, lower HAZ, and smarter THC tuning—plus a key choice that changes everything.

Because plasma keyhole robots slash heat input and cycle time while demanding disciplined programming and smart ROI tradeoffs, discover the pitfalls that could quietly erase your margins.

Fine-tune your plasma cuts with Standard, FineCut, and Gouging tips—discover how tip choice, amperage, and setup transform kerf, edge quality, and productivity.