Is a Plasma Cutter Better Than a Torch? Speed, Cost & Quality

Balancing speed, cost, and cut quality, discover whether plasma or oxy-fuel wins for your shop—before you invest in the wrong tool.

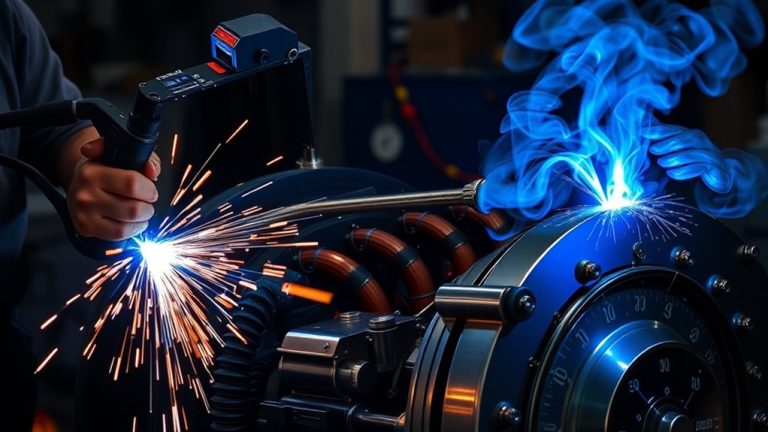

Get precise, high-speed metal cutting with a plasma cutter. Choose from portable 110/220V machines to heavy-duty shop units, with options like pilot-arc for cutting through paint or rust, CNC-ready interfaces, and built-in air compressors for true plug-and-play setup. Dial in amperage, air pressure, and torch height for smooth kerf, minimal dross, and tight tolerances on steel, stainless steel, and aluminum. Ideal for fabrication, auto repair, maintenance, and custom projects.

Balancing speed, cost, and cut quality, discover whether plasma or oxy-fuel wins for your shop—before you invest in the wrong tool.

Learn how a plasma cutter at 220V can transform your projects with impressive cutting capacities and speeds. Discover how these capabilities can enhance your tasks.

Master the art of plasma cutting with a generator by understanding clean power, wattage, and THD—discover the crucial final step to optimize your setup.

Know the secrets to maximizing a 120V plasma cutter's efficiency and learn how to tackle its limitations with expert tips on amperage settings.

A quick guide to what metals plasma cutters slice, how thickness and amperage affect results, and the essential setup for crisp cuts you can’t afford to miss.

Compare Lotos plasma cutter amp requirements for 120V and 240V models; discover how these differences impact your cutting performance and find the best fit.

Gain insights into plasma cutter power needs—amps, voltage, phase—and discover how to ensure optimal cutting performance. Ready to elevate your cutting game?

Boost your shop’s efficiency with practical plasma cutter uses—from fast cuts to smart nesting—and discover the workflows that unlock real payoff.

Solve the mystery of plasma cutter voltages as we uncover the roles of input and output, and their effects on CNC systems.

Want to know if plasma arcs really reach 30,000°C and what limits them? Discover the gas, current, and geometry factors that set real welding temperatures.