How Safe Is a Plasma Cutter? Hazards, Myths & Safety Tips

Master the art of plasma cutting safely by debunking myths and learning essential safety tips to protect yourself from hidden hazards.

Get precise, high-speed metal cutting with a plasma cutter. Choose from portable 110/220V machines to heavy-duty shop units, with options like pilot-arc for cutting through paint or rust, CNC-ready interfaces, and built-in air compressors for true plug-and-play setup. Dial in amperage, air pressure, and torch height for smooth kerf, minimal dross, and tight tolerances on steel, stainless steel, and aluminum. Ideal for fabrication, auto repair, maintenance, and custom projects.

Master the art of plasma cutting safely by debunking myths and learning essential safety tips to protect yourself from hidden hazards.

Keep your fingers intact by understanding the real risks of plasma cutting and discovering essential safety practices that might just save a limb.

Optimize your plasma cutting safety with essential gloves; discover crucial features and top picks to protect against heat and sparks.

Get informed about the risks of flash burns from plasma cutters, their symptoms, and prevention measures to ensure safety in your work environment.

Plasma cutting demands precision and protection; discover the ideal lens shade using our chart to ensure your safety and enhance your work.

Helmet or goggles for plasma cutting? Uncover the best choice to ensure your safety and optimal protection in various work conditions.

Master plasma cutter safety with essential rules, PPE tips, and a crucial setup checklist that ensures your safety—discover what's missing in your routine.

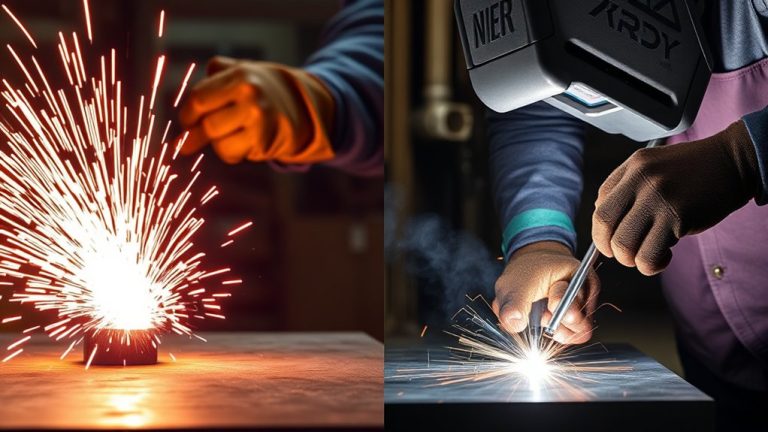

Discover the distinct roles and safety measures of plasma cutters and welding machines—are they different or more alike than you think?

Thinking plasma cutters might weld? Discover their true capabilities and limitations, and what this means for your projects.

Learn why using a plasma cutter for TIG welding presents challenges due to their distinct requirements; discover their unique roles in metalwork. Read on to find out more!