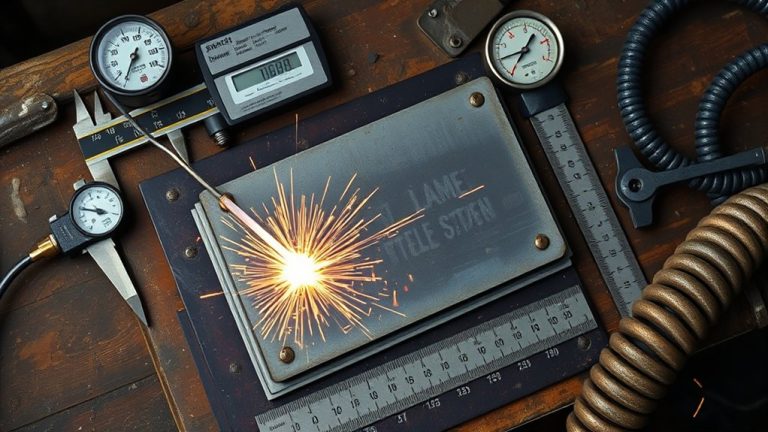

Plasma Cutter Limitations: Thickness, Precision & Edge Quality

Investigate the nuanced constraints of plasma cutting in thickness, precision, and edge quality to revolutionize your metalwork mastery.

Get precise, high-speed metal cutting with a plasma cutter. Choose from portable 110/220V machines to heavy-duty shop units, with options like pilot-arc for cutting through paint or rust, CNC-ready interfaces, and built-in air compressors for true plug-and-play setup. Dial in amperage, air pressure, and torch height for smooth kerf, minimal dross, and tight tolerances on steel, stainless steel, and aluminum. Ideal for fabrication, auto repair, maintenance, and custom projects.

Investigate the nuanced constraints of plasma cutting in thickness, precision, and edge quality to revolutionize your metalwork mastery.

Gain insights into plasma cutting's challenges, from dross to HAZ, and understand maintenance impacts; discover how these factors could affect your projects.

Master the art of cutting with plasma cutters; explore their versatility across materials and thicknesses to discover endless industrial applications.

Optimizing energy use and cost, plasma cutting's impressive efficiency and speed might redefine your expectations—discover the details inside.

Learn the exact amps, IPM, and air pressure for each steel thickness with pro tips on standoff and duty cycle—discover the optimized chart inside.

Master plasma cutting aluminum by dialing voltage, amperage, standoff, and gas for smoother edges and speed—discover the exact settings that prevent dross and warping.

Learn how 40A vs 60A plasma settings affect thickness, speed, and cut quality—plus the critical tuning factor that can make or break your results.

A 40‑amp plasma cutter promises clean cuts around 1/4 inch but can sever near 1 inch—discover the trade-offs, techniques, and specs that decide your results.

Get the real 220V plasma cutting thickness by amps—see how 20–50 A maps to steel size, duty cycle, tip selection, and circuit needs before you cut.

Unlock the Plasma Cutter 62i’s real-world thickness limits and discover the overlooked factors that make or break your cuts—ready to push beyond the spec sheet?