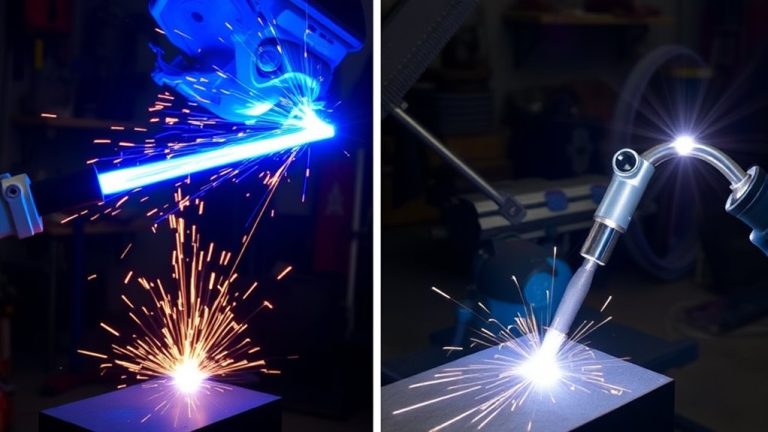

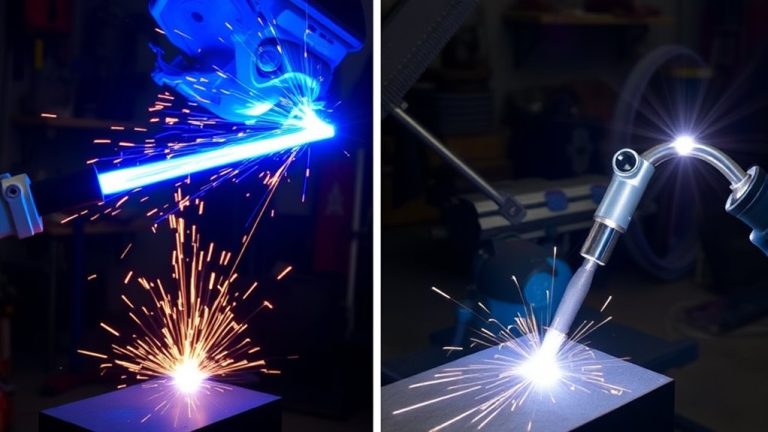

Plasma Welding Vs TIG Welding: Precision, Heat Input & Applications

Navigate the intricacies of plasma and TIG welding, uncovering how they differ in precision and heat control—discover which is best for your project.

Navigate the intricacies of plasma and TIG welding, uncovering how they differ in precision and heat control—discover which is best for your project.

Keen to avoid costly misfits in your plasma torch? Learn which consumables truly interchange—and which ruin cuts—before your next slice.

A plasma cutter unlocks fast, precise metal cutting, beveling, and gouging across steel, aluminum, and stainless—discover practical projects and pro tips you shouldn’t miss.

Plasma cutters precisely slice steel, aluminum, and exotic alloys in everyday industries—promising tight tolerances and safety—yet their most unexpected applications might surprise you.

Plasma Cutter Consumables Explained: pro tips on electrodes, nozzles, and shields for cleaner cuts—discover the small parts that make or break your next pass.

Keen to discover which welding method offers the best speed, penetration, and cost-effectiveness for your project? Find out more inside!

Journey through plasma cutter consumables—electrodes, nozzles, swirl rings, caps—and discover how each part shapes precision, safety, and performance before your next cut.

Optimize your cuts: compare plasma cutter vs band saw on accuracy, edge finish, and cost to see which truly fits your shop needs.

Watch how plasma cutters and angle grinders stack up on speed, cut quality, cost, and safety—and discover which tool wins for your next metal job.

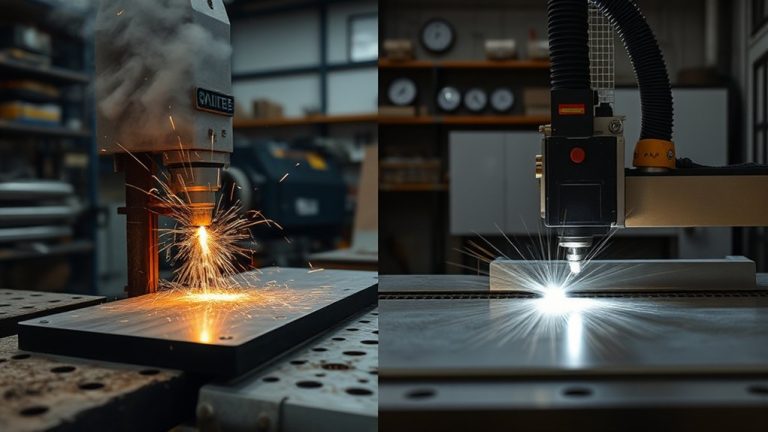

The ultimate guide compares plasma vs laser cutters on cost, speed, quality, and use cases—discover which fits your project before you make an expensive mistake.